Toyota Tacoma (2015-2018) Service Manual: Disassembly

DISASSEMBLY

PROCEDURE

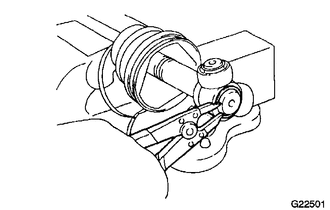

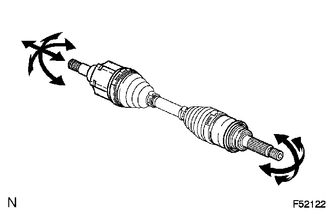

1. INSPECT FRONT DRIVE SHAFT

(a) Check whether there is no remarkable play in the outboard joint.

(b) Check whether the inboard joint slides smoothly in the thrust direction.

(c) Check whether there is no remarkable play in the radial direction of the inboard joint.

(d) Check the boots for damage.

NOTICE:

Move the drive shaft while keeping it level.

2. REMOVE FRONT AXLE INBOARD JOINT BOOT CLAMP

(a) Using pliers, disengage the hooks together and remove the large clamp.

(b) Using a side cutter, cut the small boot clamp.

3. SEPARATE INBOARD JOINT BOOT

(a) Slide the inboard joint boot toward the outboard joint.

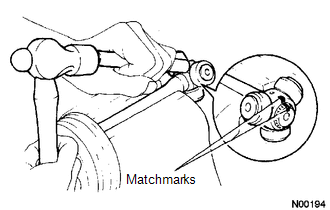

4. REMOVE FRONT DRIVE INBOARD JOINT ASSEMBLY

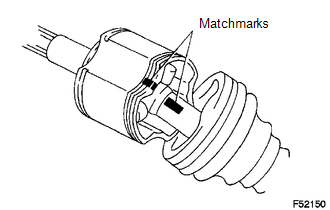

(a) Place matchmarks on the inboard joint and outboard joint shaft.

NOTICE:

Do not punch the marks.

(b) Remove the inboard joint from the outboard joint shaft.

|

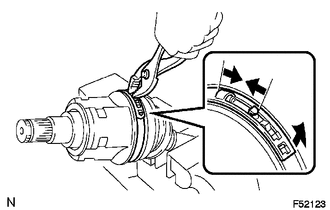

(c) Using a snap ring expander, remove the snap ring. |

|

|

(d) Place matchmarks on the outboard joint shaft and tripod. NOTICE: Do not punch the marks. |

|

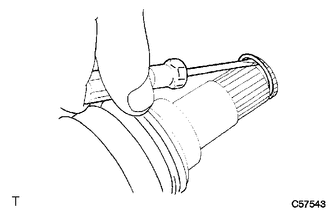

(e) Using a brass bar and hammer, remove the tripod from the outboard joint shaft.

NOTICE:

Do not tap the roller.

(f) Remove the inboard joint boot from the outboard joint shaft.

5. REMOVE FRONT AXLE OUTBOARD JOINT BOOT CLAMP

(a) Using a side cutter, cut the boot clamps.

6. REMOVE OUTBOARD JOINT BOOT

(a) Remove the outboard joint boot from the outboard joint shaft.

7. REMOVE FRONT DRIVE INNER SHAFT OUTER SHAFT SNAP RING

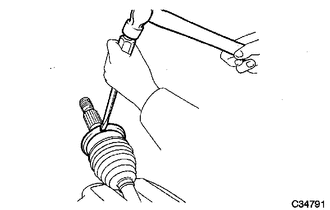

(a) Using a screwdriver, remove the snap ring.

8. REMOVE FRONT DRIVE SHAFT DUST COVER

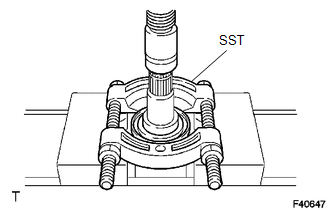

(a) Using SST and a press, remove the dust cover.

SST: 09950-00020

9. REMOVE FRONT AXLE HUB OIL SEAL

(a) Using a screwdriver and a hammer, remove the oil seal.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEEL

2. DRAIN DIFFERENTIAL OIL

3. SEPARATE FRONT SPEED SENSOR

(a) Remove the bolt and separate the front speed sensor.

(b) Disengage the 2 clamps.

(c) Remov ...

Other materials:

Precaution

PRECAUTION

1. IGNITION SWITCH EXPRESSIONS

(a) The type of ignition switch used on this model differs depending on the specifications

of the vehicle. The expressions listed in the table below are used in this section.

Expression

Ignition Switch (Position)

Engine ...

Installation

INSTALLATION

PROCEDURE

1. ADJUST COMPRESSOR OIL

(a) for HFC-134a (R134a):

(1) When replacing the compressor and magnetic clutch with new ones, after gradually

discharging the refrigerant gas from the service valve, drain the following volume

of oil from new compressor and magnetic clutch bef ...

Installation

INSTALLATION

PROCEDURE

1. INSPECT AND ADJUST BRAKE BOOSTER PUSH ROD

NOTICE:

The brake booster interior must not be a vacuum when adjusting the booster. Stop

the engine and depress the brake pedal several times until there is no vacuum in

the booster.

HINT:

Adjust the booster push rod when ...