Toyota Tacoma (2015-2018) Service Manual: Installation

INSTALLATION

PROCEDURE

1. INSPECT AND ADJUST BRAKE BOOSTER PUSH ROD

NOTICE:

The brake booster interior must not be a vacuum when adjusting the booster. Stop the engine and depress the brake pedal several times until there is no vacuum in the booster.

HINT:

Adjust the booster push rod when the master cylinder sub-assembly is replaced with a new one. Adjustment is not necessary when the master cylinder sub-assembly is reinstalled and the booster is replaced with a new one.

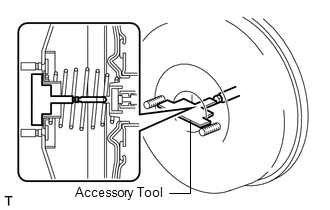

(a) Apply chalk to the tip of an accessory tool.

HINT:

The accessory tool is enclosed with a new brake master cylinder sub-assembly.

|

(b) Place the accessory tool on the brake booster assembly. |

|

(c) Measure the clearance between the brake booster push rod and accessory tool.

Standard clearance:

0 mm (0 in.)

HINT:

Adjust the clearance in the following cases:

- If there is a clearance between the accessory tool and the shell of the brake booster (floating accessory tool), the push rod is protruding too far.

- If the chalk does not stick on the tip of the brake booster push rod, the push rod protrusion is insufficient.

|

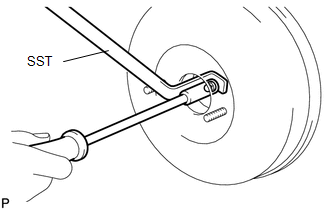

(d) If the clearance is not as specified, adjust the push rod length by holding the rod using SST and turning the tip of the rod using a socket driver (7 mm). SST: 09737-00020 HINT: Check the push rod clearance again after adjustment. |

|

2. INSTALL BRAKE MASTER CYLINDER SUB-ASSEMBLY

(a) Install a new O-ring onto the brake master cylinder sub-assembly.

|

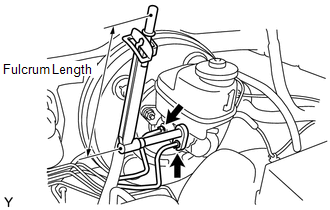

(b) Install the brake master cylinder sub-assembly with the 2 nuts onto the brake booster. Torque: 13 N·m {127 kgf·cm, 9 ft·lbf} |

|

|

(c) Using a union nut wrench, connect the 2 brake lines to the brake master cylinder sub-assembly. Torque: without union nut wrench : 20 N·m {199 kgf·cm, 14 ft·lbf} with union nut wrench : 18 N·m {187 kgf·cm, 13 ft·lbf} HINT:

|

|

|

(d) Connect the brake fluid level warning switch connector to the brake master cylinder sub-assembly. |

|

3. INSTALL CLUTCH RESERVOIR TUBE (for Manual Transmission)

|

(a) Connect the clutch reservoir tube to the reservoir. |

|

4. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Torque:

5.4 N·m {55 kgf·cm, 48 in·lbf}

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

Click here .gif)

5. FILL RESERVOIR WITH BRAKE FLUID

Click here .gif)

6. BLEED MASTER CYLINDER

Click here .gif)

7. BLEED BRAKE LINE

Click here .gif)

8. BLEED BRAKE ACTUATOR

Click here .gif)

9. INSPECT FLUID LEVEL IN RESERVOIR

Click here .gif)

10. INSPECT FOR BRAKE FLUID LEAK

11. INSPECT BRAKE PEDAL HEIGHT

Click here .gif)

12. INSPECT PEDAL FREE PLAY

Click here .gif)

13. INSPECT PEDAL RESERVE DISTANCE

Click here .gif)

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

Release the vacuum from booster by depressing the brake pedal several times.

Then remove the brake master cylinder from brake booster.

PROCEDURE

1. PRECAU ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL MASTER CYLINDER RESERVOIR GROMMET

(a) Apply lithium soap base glycol grease to 2 new grommets.

(b) Install the 2 grommets onto the brake master cylinder reservoir.

...

Other materials:

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE BRAKE MASTER CYLINDER RESERVOIR FILLER CAP ASSEMBLY

2. REMOVE BRAKE MASTER CYLINDER RESERVOIR STRAINER

3. REMOVE BRAKE MASTER CYLINDER RESERVOIR ASSEMBLY

(a) Fix the brake master cylinder in a vise between aluminum plates.

NOTICE:

Do not overtighten the vise.

...

Driver Side Door ECU Communication Stop (B2321)

DESCRIPTION

This DTC is stored when LIN communication between the front power window regulator

motor assembly LH and main body ECU (multiplex network body ECU) stops for 10 seconds

or more.

DTC No.

DTC Detection Condition

Trouble Area

B2321

...

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for both the RH and LH sides.

The procedure described below is for the LH side.

PROCEDURE

1. PRECAUTION

CAUTION:

Be sure to read Precaution thoroughly before servicing (See page

).

NOTICE:

After turning the ign ...

.png)

.png)

.png)