Toyota Tacoma (2015-2018) Service Manual: Center Differential Lock Position Switch (C1282)

DESCRIPTION

DTC C1282 is stored only in test mode.

|

DTC Code |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

C1282 |

Stored during test mode. |

|

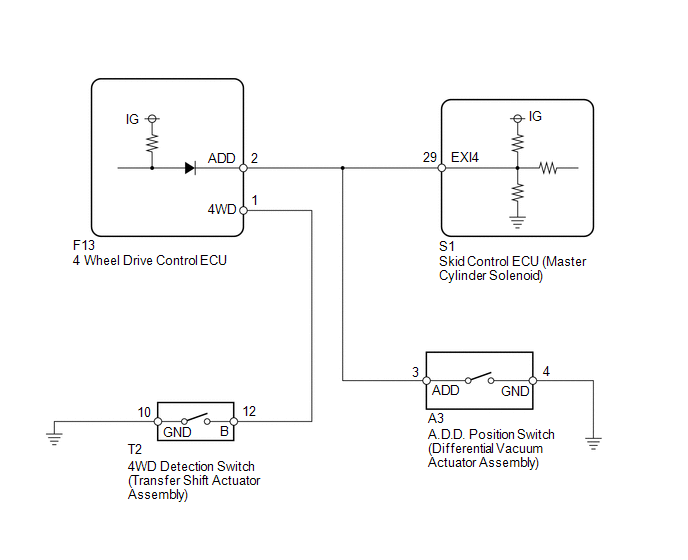

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

When replacing the skid control ECU (master cylinder solenoid), perform calibration

(See page .gif)

.gif) ).

).

PROCEDURE

|

1. |

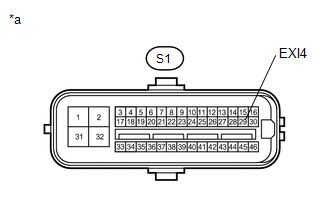

INSPECT SKID CONTROL ECU (EXI4) |

(a) Disconnect the S1 skid control ECU (master cylinder solenoid) connector.

|

(b) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| NG | .gif) |

GO TO STEP 3 |

|

|

2. |

CHECK TEST MODE DTC |

(a) Switch the vehicle to test mode, perform the 4WD detection switch signal

check, and then check that DTC C1282 is cleared (See page

.gif)

.gif) ).

).

|

Result |

Proceed to |

|---|---|

|

DTC is not cleared |

A |

|

DTC is cleared |

B |

| A | .gif) |

REPLACE MASTER CYLINDER SOLENOID |

| B | .gif) |

USE SIMULATION METHOD TO CHECK |

|

3. |

CHECK HARNESS AND CONNECTOR (SKID CONTROL ECU - 4 WHEEL DRIVE CONTROL ECU AND A.D.D. POSITION SWITCH) |

(a) Disconnect the S1 skid control ECU (master cylinder solenoid) connector.

(b) Disconnect the F13 4 wheel drive control ECU connector.

(c) Disconnect the A3 A.D.D. position switch (differential vacuum actuator assembly) connector.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

S1-29 (EXI4) - F13-2 (ADD) |

Always |

Below 1 Ω |

|

S1-29 (EXI4) - A3-3 (ADD) |

Always |

Below 1 Ω |

|

S1-29 (EXI4) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif) |

GO TO TRANSFER SYSTEM (PROBLEM SYMPTOMS TABLE) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

ECM Communication Circuit Malfunction (C1203)

ECM Communication Circuit Malfunction (C1203)

DESCRIPTION

The circuit sends TRAC, A-TRAC and VSC control information from the skid control

ECU (master cylinder solenoid) to the ECM, and engine control information from the

ECM to the skid con ...

Steering Angle Sensor Zero Point Malfunction (C1290)

Steering Angle Sensor Zero Point Malfunction (C1290)

DESCRIPTION

The skid control ECU (master cylinder solenoid) acquires steering angle sensor

zero point every time the ignition switch is turned to ON and the vehicle is driven

at 35 km/h (22 mph) ...

Other materials:

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) Smart key system (for start function) data and the Diagnostic Trouble Codes

(DTCs) can be read through the Data Link Connector 3 (DLC3) of the vehicle. When

the system seems to be malfunctioning, use the Techstream to check for malfunctions

and perform rep ...

Short to GND in Outer Mirror Indicator(Master) (C1AB2)

DESCRIPTION

This DTC is stored when the blind spot monitor sensor LH detects a ground short

in the blind spot monitor indicator LH.

DTC Code

DTC Detection Condition

Trouble Area

C1AB2

With the blind spot monitor main switch assembly (w ...

Low Power Supply Voltage Malfunction (C1241)

DESCRIPTION

If a malfunction is detected in the power supply circuit, the skid control ECU

(brake actuator assembly) stores this DTC and the fail-safe function prohibits ABS

operation.

This DTC is stored when the +BS terminal voltage deviates from the DTC detection

condition due to a malfunc ...

.gif)