Toyota Tacoma (2015-2018) Service Manual: Air Fuel Ratio Sensor

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE AIR FUEL RATIO SENSOR (for Bank 1 Sensor 1)

|

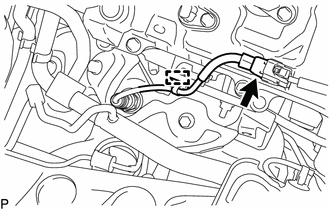

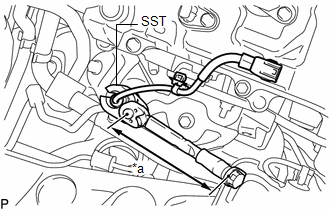

(a) Disconnect the air fuel ratio sensor connector. |

|

(b) Disengage the clamp to separate the air fuel ratio sensor wire.

|

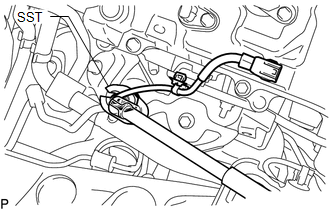

(c) Using SST, remove the air fuel ratio sensor from the exhaust manifold sub-assembly RH. SST: 09224-00011 |

|

2. REMOVE AIR FUEL RATIO SENSOR (for Bank 2 Sensor 1)

|

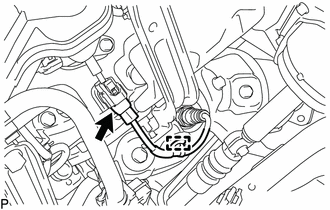

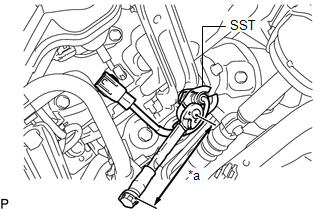

(a) Disconnect the air fuel ratio sensor connector. |

|

(b) Disengage the clamp to separate the air fuel ratio sensor wire.

|

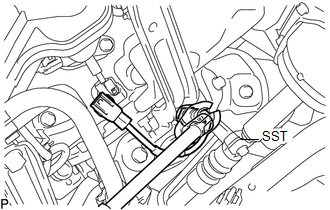

(c) Using SST, remove the air fuel ratio sensor from the exhaust manifold sub-assembly LH. SST: 09224-00011 |

|

Inspection

INSPECTION

PROCEDURE

1. INSPECT AIR FUEL RATIO SENSOR

|

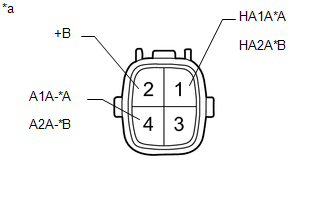

(a) Measure the resistance according to the value(s) in the table below. Text in Illustration

Standard Resistance (for Bank 1 Sensor 1):

Standard Resistance (for Bank 2 Sensor 1):

If the result is not as specified, replace the air fuel ratio sensor. |

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL AIR FUEL RATIO SENSOR (for Bank 1 Sensor 1)

HINT:

Perform "Inspection After Repair" after replacing the air fuel ratio sensor (See

page .gif) ).

).

|

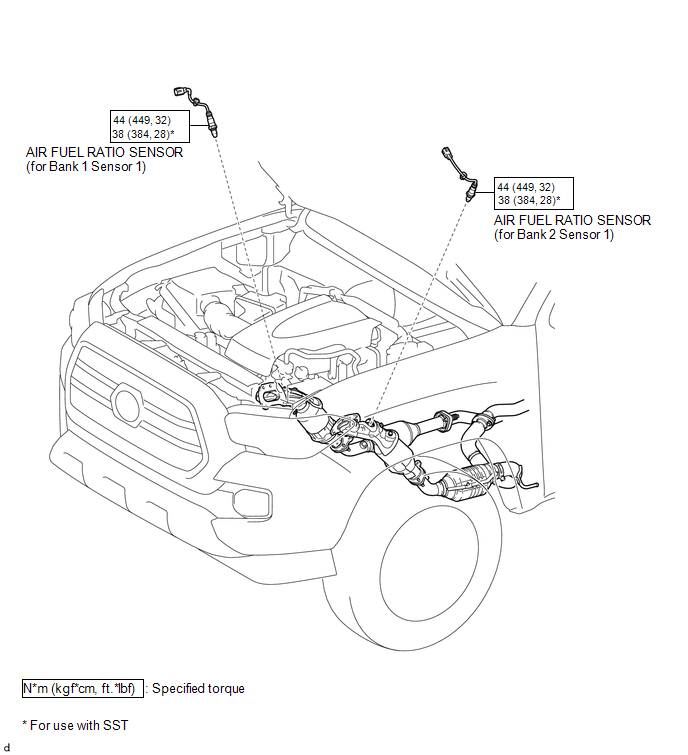

(a) Using SST, install the air fuel ratio sensor to the exhaust manifold sub-assembly RH. Text in Illustration

SST: 09224-00011 Torque: Specified tightening torque : 44 N·m {449 kgf·cm, 32 ft·lbf} HINT:

|

|

(b) Engage the clamp to install the air fuel ratio sensor wire.

(c) Connect the air fuel ratio sensor connector.

2. INSTALL AIR FUEL RATIO SENSOR (for Bank 2 Sensor 1)

HINT:

Perform "Inspection After Repair" after replacing the air fuel ratio sensor (See

page .gif) ).

).

|

(a) Using SST, install the air fuel ratio sensor to the exhaust manifold sub-assembly LH. Text in Illustration

SST: 09224-00011 Torque: Specified tightening torque : 44 N·m {449 kgf·cm, 32 ft·lbf} HINT:

|

|

(b) Engage the clamp to install the air fuel ratio sensor wire.

(c) Connect the air fuel ratio sensor connector.

Accelerator Pedal

Accelerator Pedal

Components

COMPONENTS

ILLUSTRATION

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT ACCELERATOR PEDAL SENSOR ASSEMBLY

(a) Connect the Techstream to the DLC3.

(b) Turn the ...

Other materials:

ECU Power Source Circuit

DESCRIPTION

This circuit supplies power to the millimeter wave radar sensor assembly when

the ignition switch is ON.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following

inspection procedure.

PROCEDURE

...

Steering Angle Sensor Internal Circuit (C1433)

DESCRIPTION

The skid control ECU (brake actuator assembly) outputs this DTC when it receives

an internal malfunction signal from the steering angle sensor.

DTC No.

Detection Item

DTC Detection Condition

Trouble Area

C1433

St ...

Communication Error from ECM to VSC (P1631)

DESCRIPTION

The ECM sends signals such as A/T information signals, dynamic radar cruise control

operation signals, brake operation demand signals, and buzzer operation demand signals

to the skid control ECU (brake actuator assembly) when the dynamic radar cruise

control is operating. Therefor ...