Toyota Tacoma (2015-2018) Service Manual: Theft Deterrent System Communication Line High Fixation (B279A,B279A12)

DESCRIPTION

If the communication line (EFIO-IMI) to the transponder key ECU assembly is stuck high (e.g. shorted to +B), the ECM stores this DTC.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

DTC Output Confirmation Operation |

|---|---|---|---|

|

B279A*1 |

Communication line (EFIO-IMI) between the ECM and transponder key ECU assembly is stuck high. |

|

Turn the ignition switch to ON and wait 6 seconds. |

|

B279A12*2 |

Communication line (EFIO-IMI) between the ECM and transponder key ECU assembly is stuck high. |

|

Turn the ignition switch to ON and wait 6 seconds. |

- *1: for 2TR-FE

- *2: for 2GR-FKS

|

Vehicle Condition when Malfunction Detected |

Fail-safe Operation when Malfunction Detected |

|---|---|

|

Engine cannot be started (initial ignition occurs and engine cranks, then ignition stops) |

Engine cannot be started |

|

DTC No. |

Data List and Active Test |

|---|---|

|

B279A*1 |

- |

|

B279A12*1 |

- |

- *1: for 2TR-FE

- *2: for 2GR-FKS

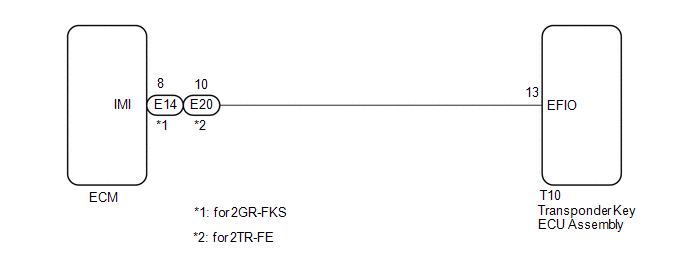

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- If the transponder key ECU assembly or ECM is replaced, refer to Registration

(See page

.gif) ).

). - After repair, confirm that no DTCs are output by performing "DTC Output Confirmation Operation".

PROCEDURE

|

1. |

CLEAR DTC |

(a) Clear the DTCs (See page .gif) ).

).

|

|

2. |

CHECK DTC OUTPUT |

(a) Perform "DTC Output Confirmation Operation" procedure.

(b) Check for DTCs (See page .gif) ).

).

|

Result |

Proceed to |

|---|---|

|

DTC B279A (for 2TR-FE) or B279A12 (for 2GR-FKS) is output |

A |

|

DTC B279A (for 2TR-FE) or B279A12 (for 2GR-FKS) is not output |

B |

| B | .gif) |

USE SIMULATION METHOD TO CHECK |

|

|

3. |

CHECK CONNECTION OF CONNECTOR |

(a) Check that the connectors are properly connected to the ECM and transponder key ECU assembly.

OK:

Connectors are properly connected.

| NG | .gif) |

CONNECT CONNECTORS PROPERLY |

|

|

4. |

CHECK HARNESS AND CONNECTOR (TRANSPONDER KEY ECU ASSEMBLY - ECM) |

(a) Disconnect the T10 transponder key ECU assembly connector.

(b) Disconnect the E14*1 or E20*2 ECM connector.

- *1: for 2GR-FKS

- *2: for 2TR-FE

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

T10-13 (EFIO) - E14-8 (IMI)*1 |

Always |

Below 1 Ω |

|

T10-13 (EFIO) or E14-8 (IMI) - Body ground*1 |

Always |

10 kΩ or higher |

|

T10-13 (EFIO) - E20-10 (IMI)*2 |

Always |

Below 1 Ω |

|

T10-13 (EFIO) or E20-10 (IMI) - Body ground*2 |

Always |

10 kΩ or higher |

- *1: for 2GR-FKS

- *2: for 2TR-FE

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

REPLACE TRANSPONDER KEY ECU ASSEMBLY |

(a) Replace the transponder key ECU assembly with a new one (See page

.gif) ).

).

|

|

6. |

CLEAR DTC |

(a) Clear the DTCs (See page .gif) ).

).

|

|

7. |

CHECK FOR DTC |

(a) Perform "DTC Output Confirmation Operation" procedure.

(b) Check for DTCs (See page .gif) ).

).

|

Result |

Proceed to |

|---|---|

|

DTC B279A (for 2TR-FE) or B279A12 (for 2GR-FKS) is not output |

A |

|

DTC B279A is output (for 2TR-FE) |

B |

|

DTC B279A12 is output (for 2GR-FKS) |

C |

| A | .gif) |

END (TRANSPONDER KEY ECU ASSEMBLY WAS DEFECTIVE) |

| B | .gif) |

REPLACE ECM |

| C | .gif) |

REPLACE ECM |

Diagnostic Trouble Code Chart

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

HINT:

If a trouble code is stored during the DTC check, inspect the trouble areas listed

for that code. For details of the code, refer to "See page" below.

...

Theft Deterrent System Presence Detection (B279C,B279C95)

Theft Deterrent System Presence Detection (B279C,B279C95)

DESCRIPTION

If an ECM that is incompatible with the engine immobiliser system is installed,

the ECM stores this DTC.

DTC No.

DTC Detection Condition

Trouble Area

...

Other materials:

Tail Gate Protector

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE TAIL GATE PROTECTOR

(a) Using a T30 "TORX" socket wrench, remove the 8 screws.

(b) Disengage the 14 claws and 3 guides to remove the tail gate protector ...

Front Camera Module Incorrect Axial Gap (C1AA8,C1AA9)

DESCRIPTION

If the forward recognition camera detects that the forward recognition camera

axis has deviated, DTC C1AA8 is stored. Also, if Forward Recognition Camera Axis

Adjustment is not performed after installing the forward recognition camera, DTC

C1AA9 is stored.

DTC No.

...

TC and CG Terminal Circuit

DESCRIPTION

DTC output mode is set by connecting terminals TC and CG of the DLC3.

The DTCs are displayed by blinking the SRS warning light.

HINT:

Make sure that DTCs which relate to the CAN communication system are

not output. If any of these DTCs are output, check the CAN communicat ...

.gif)