Toyota Tacoma (2015-2018) Service Manual: Terminals Of Ecm

TERMINALS OF ECM

HINT:

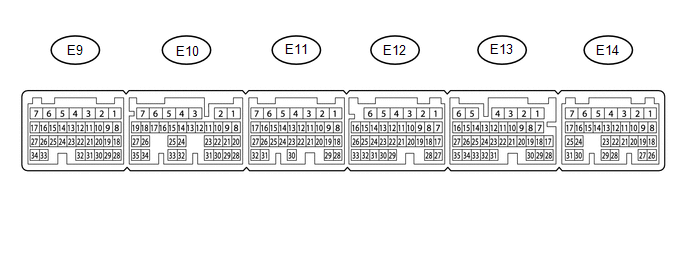

The standard normal voltage between each pair of ECM terminals is shown in the table below. The appropriate conditions for checking each pair of terminals are also indicated. The result of checks should be compared with the standard normal voltage for that pair of terminals, displayed in the Specified Condition column. The illustration above can be used as a reference to identify the ECM terminal locations.

|

Terminal No. (Symbol) |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|---|---|---|---|---|

|

E14-2 (BATT) - E11-1 (E1) |

L - W-B |

Battery (for measuring battery voltage and for ECM memory) |

Always |

11 to 14 V |

|

E12-6 (+BM) - E11-1 (E1) |

GR - W-B |

Power source of throttle actuator |

Always |

11 to 14 V |

|

E14-3 (+B) - E11-1 (E1) |

B - W-B |

Power source of ECM |

Ignition switch ON |

11 to 14 V |

|

E14-4 (+B2) - E11-1 (E1) |

B - W-B |

Power source of ECM |

Ignition switch ON |

11 to 14 V |

|

E14-25 (MREL) - E11-1 (E1) |

GR - W-B |

EFI-MAIN NO. 1 relay operation signal |

Ignition switch ON |

11 to 14 V |

|

E9-26 (VCNE) - E11-1 (E1) |

R - W-B |

Power source of crankshaft position sensor (specific voltage) |

Ignition switch ON |

4.5 to 5.5 V |

|

E9-25 (NE+) - E9-33 (NE-) |

B - G |

Crankshaft position sensor |

Idling |

Pulse generation |

|

E13-24 (SPD) - E11-1 (E1) |

R - W-B |

Vehicle speed signal from combination meter assembly |

Driving at 20 km/h (12 mph) |

Pulse generation |

|

E11-1 (E1) - Body ground |

W-B - Body ground |

Ground circuit of ECM |

Always |

Below 1 Ω |

Diagnosis System

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) To check DTCs, connect the Techstream to the Data Link Connector 3 (DLC3)

of the vehicle. The Techstream displays DTCs and freeze frame data. The DTCs and

fre ...

Check Mode Procedure

Check Mode Procedure

CHECK MODE PROCEDURE

1. DESCRIPTION

Check mode has a higher sensitivity to malfunctions and can detect malfunctions

that cannot be detected in normal mode. Check mode can also detect all of the ma ...

Other materials:

Transfer System

Precaution

PRECAUTION

Before disassembly, clean the transfer assembly and remove any deposited

sand and mud to prevent it from entering the transfer during disassembly

and assembly.

When removing any light alloy parts such as the transfer covers, do

not pry them off with a ...

Engine

General Maintenance

GENERAL MAINTENANCE

CAUTION / NOTICE / HINT

HINT:

Inspect these items when the engine is cold.

PROCEDURE

1. REPLACE CHAIN SUB-ASSEMBLY

HINT:

2TR-FE: See page

2GR-FKS: See page

2. INSPECT DRIVE BELT

HINT:

2TR-FE: See page

2GR-FKS: ...

Air Inlet Control Servo Motor

Inspection

INSPECTION

PROCEDURE

1. INSPECT AIR INLET CONTROL SERVO MOTOR

(a) Inspect the servo motor operation.

(1) Connect the positive (+) lead from the battery to terminal 1 (FRS)

and negative (-) lead to terminals 2 (REC), then check that the shaft rotates

clockwise s ...