Toyota Tacoma (2015-2018) Service Manual: Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repairs" after replacing the fuel delivery pipe assembly

LH (fuel pressure sensor) (See page .gif) ).

).

PROCEDURE

1. INSTALL FUEL PIPE PLUG SUB-ASSEMBLY

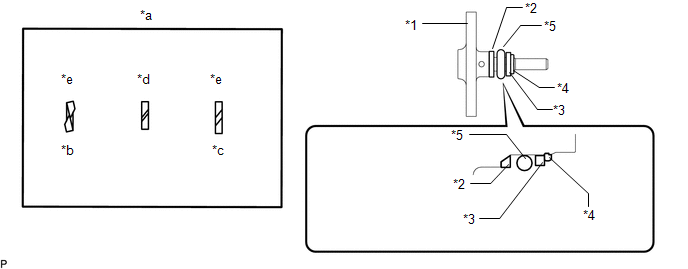

(a) Install a new O-ring, new No. 1 fuel injector back-up ring, new No. 2 fuel injector back-up ring and new No. 3 fuel injector back-up ring to the fuel pipe plug sub-assembly as shown in the illustration.

Text in Illustration

Text in Illustration

|

*1 |

Fuel Pipe Plug Sub-assembly |

*2 |

No. 1 Fuel Injector Back-up Ring |

|

*3 |

No. 3 Fuel Injector Back-up Ring |

*4 |

No. 3 Fuel Injector Back-up Ring |

|

*5 |

O-ring |

- |

- |

|

*a |

Opening |

*b |

Overlapping |

|

*c |

Stretched |

*d |

Correct |

|

*e |

Incorrect |

- |

- |

NOTICE:

- Check that there is no foreign matter or damage on the O-ring groove of the fuel pipe plug sub-assembly.

- Check that the No. 1 fuel injector back-up ring and No. 3 fuel injector back-up ring are installed in the correct orientation.

- Make sure that the No. 1 fuel injector back-up ring, No. 2 fuel injector back-up ring, No. 3 fuel injector back-up ring and O-ring are installed in the correct order.

- Check that the alignment of the No. 1 fuel injector back-up ring is not overlapped or stretched as shown in the illustration.

- After installing the O-ring, check that it is not contaminated with foreign matter and is not damaged.

(b) Secure the fuel delivery pipe assembly LH in a vise between aluminum plates.

NOTICE:

Do not overtighten the vise.

|

(c) Install a new gasket to the fuel pipe plug sub-assembly as shown in the illustration. |

|

(d) Using a 5 mm hexagon wrench, install the fuel pipe plug sub-assembly to the fuel delivery pipe assembly LH with the 2 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(e) Install a new dust cap sub-assembly to the fuel pipe plug sub-assembly.

2. INSTALL FUEL DELIVERY PIPE ASSEMBLY LH (FUEL PRESSURE SENSOR)

(See page .gif) )

)

NOTICE:

- Do not remove the fuel pressure sensor from the fuel delivery pipe sub-assembly LH.

- If a fuel pressure sensor is removed, replace the fuel delivery pipe sub-assembly LH (fuel pressure sensor) with a new one.

HINT:

Perform "Inspection After Repairs" after replacing the fuel delivery pipe assembly

LH (fuel pressure sensor) (See page .gif) ).

).

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL DELIVERY PIPE SUB-ASSEMBLY LH (FUEL PRESSURE SENSOR)

NOTICE:

Do not remove the fuel pressure sensor from the fuel delivery pipe sub-assembly

LH.

...

Fuel Pump

Fuel Pump

...

Other materials:

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" column of the

table. Check each sy ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL COOLER CONDENSER ASSEMBLY

(a) Engage the 2 claws to install the 2 condenser upper brackets.

(b) Engage the 2 claws to install the 2 condenser lower brackets.

(c) Lift the cooler condenser assembly up from the rear side of the vehicle,

and install ...

Unable to Lock Steering Wheel

DESCRIPTION

The steering lock actuator assembly activates the steering lock motor and moves

the lock bar into the steering column to lock the steering.

When the steering lock is operating, the steering may not lock when the lock

bar is not aligned with the lock hole of the steering column. In ...