Toyota Tacoma (2015-2018) Service Manual: Installation

INSTALLATION

PROCEDURE

1. INSTALL PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY

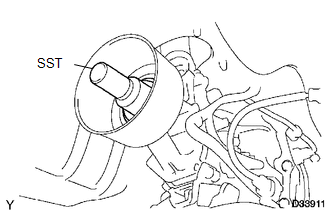

(a) Remove SST from the extension housing.

(b) Install the propeller shaft to the extension housing.

(c) Completely remove any oil or the like and clean the contact surfaces of the propeller shaft flange and differential flange.

|

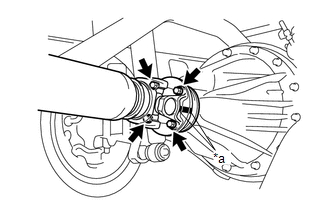

(d) Align the matchmarks on the propeller shaft flange and differential flange. Text in Illustration

|

|

(e) for Differential Type BD20:

(1) Install the propeller shaft with the 4 bolts, 4 washers and 4 nuts.

Torque:

88 N·m {899 kgf·cm, 65 ft·lbf}

(f) for Differential Type BD22:

(1) Install the propeller shaft with the 4 washers and 4 nuts.

Torque:

88 N·m {899 kgf·cm, 65 ft·lbf}

|

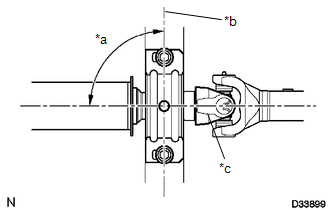

(g) Temporarily install the center No. 2 support bearing assembly with the 2 bolts. Text in Illustration

HINT: Make sure the bearing is installed with the drain hole facing downwards. |

|

|

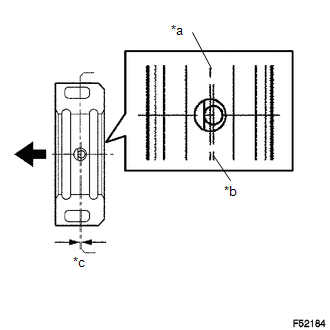

(h) Adjust the center No. 2 support bearing assembly. Text in Illustration

HINT:

|

|

(i) Tighten the 2 bolts.

Torque:

36 N·m {369 kgf·cm, 27 ft·lbf}

2. INSPECT FOR TRANSMISSION OIL LEAK

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY

(a) Using a dial indicator, check the propeller shaft with center bearing assembly

runout.

Maximum runout:

0.6 mm ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSPECT CENTER NO. 2 SUPPORT BEARING ASSEMBLY

(a) When turning the center No. 2 support bearing assembly with your hand, check

that it turns smoothly without catching an ...

Other materials:

A-TRAC Indicator Light Remains ON

DESCRIPTION

This is the A-TRAC main switch circuit. When the A-TRAC switch is turned on with

the transfer in L4, the A-TRAC function is available and the A-TRAC indicator light

illuminates.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

When replacing the skid control ECU (master ...

Radio Receiver Power Source Circuit

DESCRIPTION

This is the power source circuit to operate the navigation receiver assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing

the following inspection procedure.

PROCEDURE

1.

...

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful because intermittent conditions or signals ...