Toyota Tacoma (2015-2018) Service Manual: Inspection

INSPECTION

PROCEDURE

1. INSPECT GENERATOR BRUSH HOLDER ASSEMBLY

|

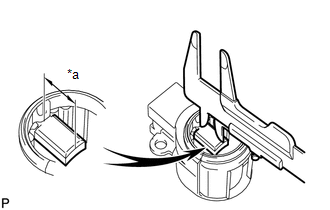

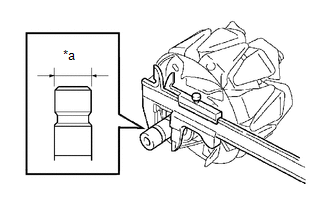

(a) Using a vernier caliper, measure the brush length. Text in Illustration

Standard exposed length: 9.5 to 11.5 mm (0.374 to 0.453 in.) Minimum exposed length: 4.5 mm (0.177 in.) If the brush length is less than the minimum, replace the generator brush holder assembly. |

|

2. INSPECT GENERATOR ROTOR ASSEMBLY

|

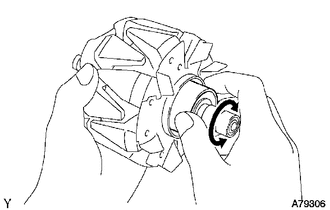

(a) Check that the generator rotor bearing is not rough or worn. If necessary, replace the generator rotor assembly. |

|

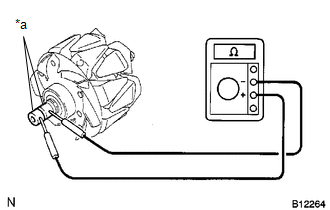

(b) Check the generator rotor assembly for an open circuit.

|

(1) Measure the resistance according to the value(s) in the table below. Text in Illustration

Standard Resistance:

If the result is not as specified, replace the generator rotor assembly. |

|

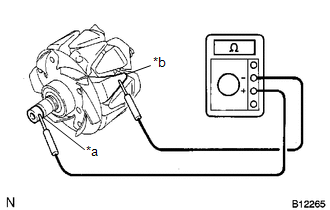

(c) Check the generator rotor assembly for an open circuit.

|

(1) Measure the resistance according to the value(s) in the table below. Text in Illustration

Standard Resistance:

If the result is not as specified, replace the generator rotor assembly. |

|

|

(d) Using a vernier caliper, measure the slip ring diameter. Text in Illustration

Standard diameter: 14.2 to 14.8 mm (0.559 to 0.583 in.) Minimum diameter: 14.0 mm (0.551 in.) If the diameter is less than the minimum, replace the generator rotor assembly. |

|

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE GENERATOR PULLEY

(a) Mount the generator assembly in the vise between aluminum plates.

NOTICE:

Do not overtighten the vise.

(b) Install SST 1-A to the generator p ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL GENERATOR ASSEMBLY

(a) Install the generator bracket to the generator assembly with the bolt.

Torque:

20 N·m {204 kgf·cm, 15 ft·lbf}

(b) Install the generat ...

Other materials:

Voice is not Recognized

PROCEDURE

1.

CHECK CONDITION

(a) Check if the system voice recognition level is low when recognizing a particular

voice.

Result

Result

Proceed to

System voice recognition level is low with any voice

A

...

Operation Check

OPERATION CHECK

1. CHECK FUNCTION

(a) Check that the key reminder warning buzzer sounds.

(1) With the driver side door closed, insert the key into the ignition key cylinder

and then turn the key to LOCK or ACC.

(2) Check that the buzzer sounds intermittently when the driver side door is

open ...

Cellular Phone Inspection

PROCEDURE

1.

CHECK USAGE CONDITION

(a) Check that the vehicle and cellular phone meet the following conditions:

NOTICE:

If changing cellular phone settings, updating software, etc. is necessary, make

sure to obtain the permission of the customer before performin ...