Toyota Tacoma (2015-2018) Service Manual: Inspection

INSPECTION

PROCEDURE

1. INSPECT AUTO HIGH BEAM SWITCH

|

*a |

Component without harness connected (Auto High Beam Switch) |

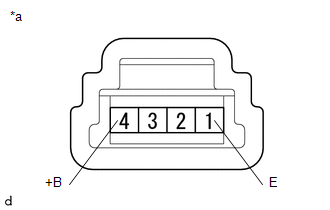

(a) Check the resistance.

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

| If the result is not as specified, replace the auto high beam switch. | ||

|

4 (+B) - 1 (E) |

Auto high beam switch ON |

Below 1 Ω |

|

Auto high beam switch OFF |

10 kΩ or higher |

|

|

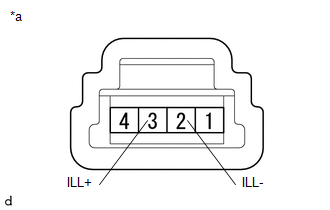

(b) Check the illumination. (1) Apply battery voltage to the connector and check the illumination condition. OK:

|

|

||||||||||

Components

Components

COMPONENTS

ILLUSTRATION

*A

for Double Cab

*B

for Access Cab

*1

AUTO HIGH BEAM SWITCH

*2

COWL SIDE TRIM ...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT DOOR SCUFF PLATE LH

for Double Cab:

Click here

for Access Cab:

Click here

2. REMOVE COWL SIDE TRIM BOARD LH

Click here

3. REMOVE INSTRUMENT CLUSTER CEN ...

Other materials:

Black Screen

PROCEDURE

1.

CHECK DISPLAY SETTING

(a) Check that the display is not in "Screen Off" mode.

OK:

The display setting is not in "Screen Off" mode.

NG

CHANGE SCREEN TO SCREEN ON MODE

OK

...

Wireless Charger Power Source Circuit

DESCRIPTION

This is the power source circuit to operate the mobile wireless charger cradle

assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following

inspection procedure.

PROCEDURE

1.

...

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. INSTALL FRONT COIL SPRING

(a) Install SST to the front coil spring, and secure SST in a vise.

SST: 09727-00 ...