Toyota Tacoma (2015-2018) Service Manual: Horn System

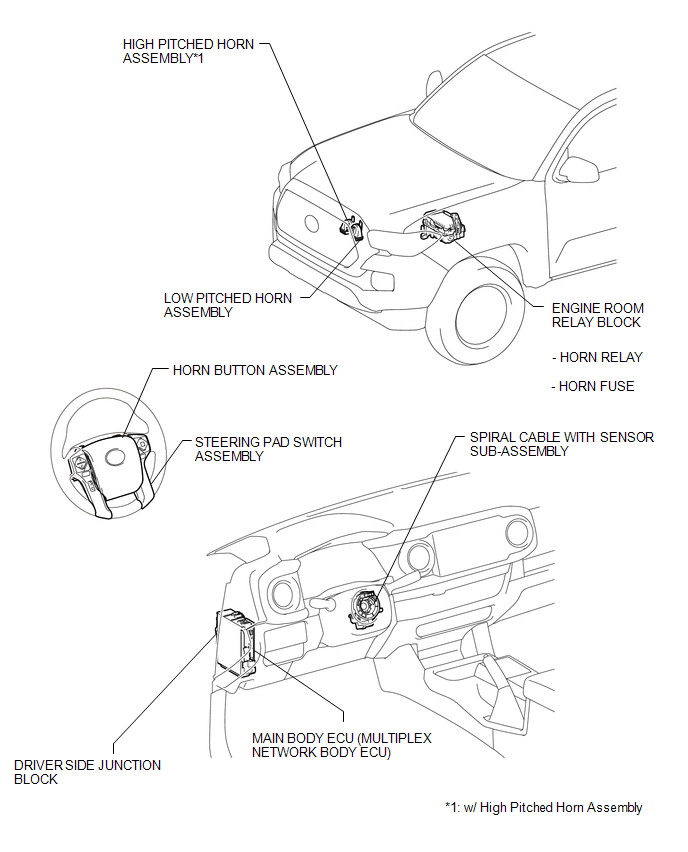

Parts Location

PARTS LOCATION

ILLUSTRATION

Precaution

PRECAUTION

1. IGNITION SWITCH EXPRESSIONS

(a) The type of ignition switch used on this model differs depending on the specifications of the vehicle. The expressions listed in the table below are used in this section.

|

Expression |

Ignition Switch (Position) |

Engine Switch (Condition) |

|---|---|---|

|

Ignition Switch off |

LOCK |

Off (Lock) |

|

Ignition Switch ACC |

ACC |

On (ACC) |

|

Ignition Switch ON |

ON |

On (IG) |

|

Engine Start |

START |

Start |

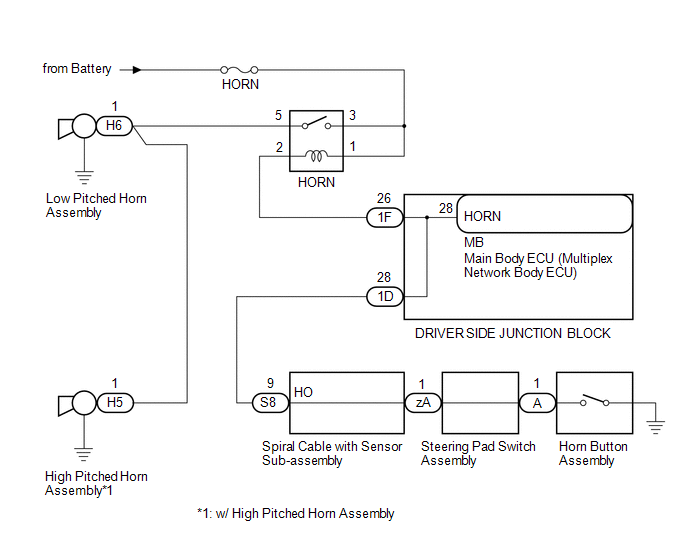

System Diagram

SYSTEM DIAGRAM

Data List / Active Test

DATA LIST / ACTIVE TEST

1. PERFORM ACTIVE TEST

HINT:

Using the Techstream to perform Active Tests allows relays, VSVs, actuators and other items to be operated without removing any parts. This non-intrusive functional inspection can be very useful because intermittent operation may be discovered before parts or wiring is disturbed. Performing Active Tests early in troubleshooting is one way to save diagnostic time. Data List information can be displayed while performing Active Tests.

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Main Body / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Main Body|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Vehicle Horn |

Vehicle horns |

ON/OFF |

- |

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms. If multiple suspected areas are listed, the potential causes of the symptoms are listed in order of probability in the "Suspected Area" column of the table. Check each symptom by checking the suspected areas in the order they are listed. Replace parts as necessary.

HORN SYSTEM|

Symptom |

Suspected Area |

See page |

|---|---|---|

|

Horn does not sound |

HORN fuse |

- |

|

HORN relay |

|

|

|

Horn button assembly |

- |

|

|

Steering pad switch assembly |

|

|

|

Spiral cable with sensor sub-assembly |

|

|

|

Driver side junction block |

- |

|

|

Harness or connector |

- |

|

|

Horn blows all the time |

HORN relay |

|

|

Horn button assembly |

- |

|

|

Steering pad switch assembly |

|

|

|

Spiral cable with sensor sub-assembly |

|

|

|

Driver side junction block |

- |

|

|

Main body ECU (Multiplex network body ECU) |

- |

|

|

Harness or connector |

- |

Horn Relay

Horn Relay

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT HORN RELAY ASSEMBLY

(a) Check the resistance.

(1) Measure the resistance according to the value(s) in the table below ...

Low Pitched Horn

Low Pitched Horn

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT LOW PITCHED HORN ASSEMBLY

(a) Check the operation.

(1) Apply battery voltage to the terminal 1 an ...

Other materials:

Terminals Of Ecu

TERMINALS OF ECU

1. CHECK SLIDING ROOF ECU (SLIDING ROOF DRIVE GEAR SUB-ASSEMBLY)

(a) Disconnect the S50 sliding roof ECU (sliding roof drive gear sub-assembly)

connector.

(b) Measure the resistance and voltage according to the value(s) in the table

below.

HINT:

Measure the values on the ...

Replacement

REPLACEMENT

PROCEDURE

1. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

(a) Start up the engine.

(b) Turn the A/C switch to ON.

(c) Operate the cooler compressor with an engine speed of approximately 1,000

rpm for 5 to 6 minutes to circulate the refrigerant and collect the compressor oil

rem ...

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful because intermittent conditions or signals ...

.gif)