Toyota Tacoma (2015-2018) Service Manual: Drive Belt

Components

COMPONENTS

ILLUSTRATION

Precaution

PRECAUTION

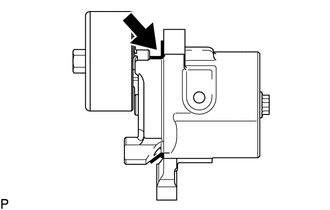

NOTICE:

- Do not apply or add oil or grease to the belt tensioner to prevent abnormal noises from the belt tensioner pulley, belt squealing, etc.

- Do not allow oil or grease to adhere to the moving parts of the belt tensioner, as this may cause malfunctions.

If oil or grease is on the location indicated by the arrow, replace the belt tensioner.

Installation

INSTALLATION

PROCEDURE

1. INSTALL FAN AND GENERATOR V BELT

|

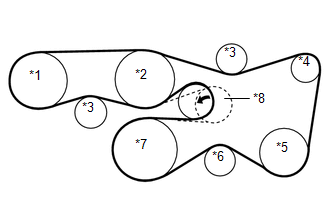

(a) Set the fan and generator V belt onto every part. Text in Illustration

|

|

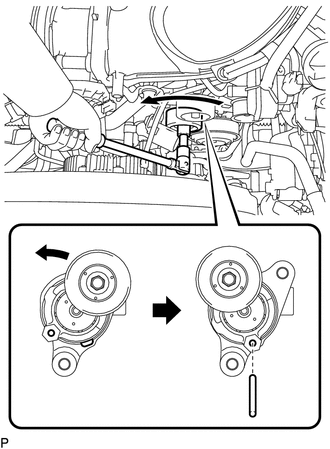

(b) While turning the V-ribbed belt tensioner counterclockwise, remove the pin.

NOTICE:

Make sure that the fan and generator V belt is properly installed to each pulley.

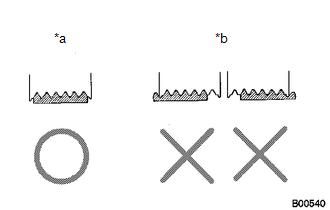

(c) Check that the belt fits properly in the ribbed grooves.

HINT:

Make sure to check by hand that the belt has not slipped out of the grooves on the bottom of the pulley.

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT FAN AND GENERATOR V BELT

|

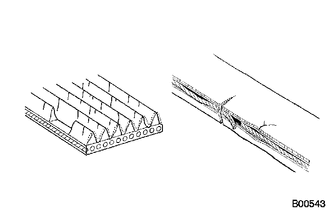

(a) Check the belt for wear, cracks or other signs of damage. If any of the following defects is found, replace the fan and generator V belt.

|

|

|

(b) Check that the belt fits properly in the ribbed grooves. Text in Illustration

HINT: Check with your hand to confirm that the belt has not slipped out of the grooves on the bottom of the pulley. If it has slipped out, replace the fan and generator V belt. Install a new fan and generator V belt correctly. |

|

2. INSPECT V-RIBBED BELT TENSIONER ASSEMBLY

(a) Check that nothing gets caught in the V-ribbed belt tensioner by turning it clockwise and counterclockwise.

If the result is not as specified, replace the V-ribbed belt tensioner.

Removal

REMOVAL

PROCEDURE

1. REMOVE FAN AND GENERATOR V BELT

|

(a) While turning the V-ribbed belt tensioner counterclockwise, align the service hole for the V-ribbed belt tensioner and the belt tensioner fixing position, and then insert a bar of 6 mm (0.236 in.) into the service hole to fix the V-ribbed belt tensioner in place. HINT: The pulley bolt for the V-ribbed belt tensioner has a left-hand thread. |

|

(b) Remove the fan and generator V belt.

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE TIMING CHAIN COVER ASSEMBLY

(See page )

2. SEPARATE NO. 2 WATER BY-PASS PIPE (for Vacuum Brake Booster)

3. REMOVE VACUUM PUMP ASSEMBLY (for Vacuum Brake Booster)

...

Engine Assembly

Engine Assembly

...

Other materials:

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT ENGINE COOLANT

(See page )

2. INSPECT ENGINE OIL

(See page )

3. INSPECT BATTERY

(See page )

4. INSPECT SPARK PLUG

(See page )

5. INSPECT AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

(a) Remove the air cleaner filter element sub-assembly.

(b) Visu ...

Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

If one of the camshaft timing gear bolts is already removed, do not remove any

other camshaft timing gear bolts.

PROCEDURE

1. REMOVE NO. 2 ENGINE UNDER COVER SUB-ASSEMBLY (w/ Off Road Package)

2. REMOVE NO. 1 ENGINE UNDER COVER SUB-ASSEMBLY

3. REMOVE ...

Transfer L4 Position Switch Circuit (C1268)

DESCRIPTION

DTC No.

Detection Item

DTC Detection Condition

Trouble Area

C1268

Transfer L4 Position Switch Circuit

Either of the following is detected:

The skid control ECU (brake actuator assembly) dete ...