Toyota Tacoma (2015-2018) Service Manual: Disassembly

DISASSEMBLY

PROCEDURE

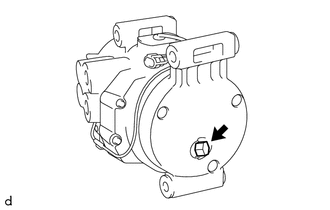

1. REMOVE PRESSURE RELIEF VALVE

(a) Remove the pressure relief valve and O-ring.

2. REMOVE MAGNET CLUTCH ASSEMBLY

(a) Secure the cooler compressor assembly in a vise between aluminum plates.

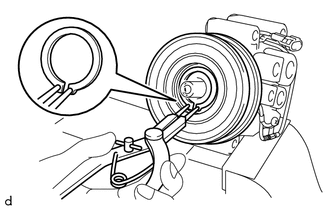

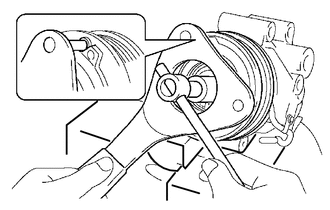

(b) Using SST, hold the magnet clutch hub.

SST: 09985-00260

(c) Remove the bolt, magnet clutch hub and compressor spacer.

HINT:

There is no set number of magnet clutch washers since they are used for adjusting.

|

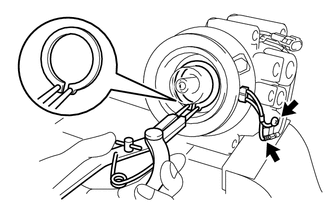

(d) Using a snap ring expander, remove the snap ring and magnet clutch rotor. NOTICE: Do not damage the seal cover of the bearing when removing the snap ring. |

|

|

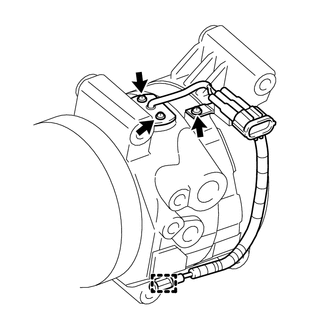

(e) Remove the screw. |

|

(f) Disconnect the connector.

(g) Using a snap ring expander, remove the snap ring and magnet clutch stator.

3. REMOVE COMPRESSOR PICK UP SENSOR

|

(a) Disengage the clamp. |

|

(b) Remove the 3 screws and compressor pick up sensor.

Removal

Removal

REMOVAL

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting

the cable from the negative (-) battery terminal. Therefore, make ...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT MAGNET CLUTCH ASSEMBLY

(a) Inspect the magnet clutch assembly.

Text in Illustration

*a

Component without harness c ...

Other materials:

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Transmitter ID not Registered (C2171/71)

DESCRIPTION

The IDs of each tire pressure warning valve and transmitter are registered to

the tire pressure warning ECU and receiver.

When the ECU detects that a transmitter ID code is not registered in the ECU,

this DTC is stored.

DTC No.

Detection Item

DTC D ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL CLUTCH PEDAL NO.1 CUSHION

(a) Install the clutch pedal No. 1 cushion to the clutch pedal sub-assembly.

2. INSTALL CLUTCH PEDAL SHAFT COLLAR

(a) Apply MP grease to the clutch pedal shaft collar.

Text in Illustration

MP grease

(b) ...