Toyota Tacoma (2015-2018) Service Manual: Disassembly

DISASSEMBLY

PROCEDURE

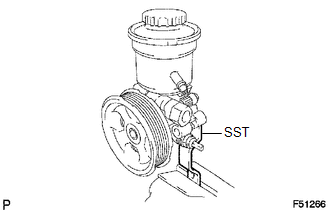

1. FIX VANE PUMP

(a) Using SST, fix the vane pump assembly in a vise.

SST: 09630-00014

09631-00132

NOTICE:

When using a vise, do not overtighten it.

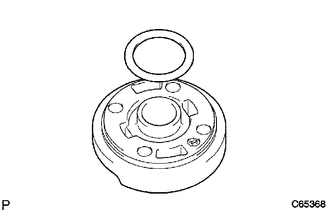

2. REMOVE VANE PUMP OIL RESERVOIR SUB-ASSEMBLY

(a) Remove the 3 bolts and vane pump oil reservoir.

(b) Remove the O-ring from the vane pump oil reservoir.

3. REMOVE FLOW CONTROL VALVE

(a) Remove the pressure port union.

(b) Remove the O-ring from the pressure port union.

(c) Remove the flow control valve and compression spring.

4. REMOVE POWER STEERING OIL PRESSURE SWITCH

NOTICE:

Be careful not to drop or badly damage the oil pressure switch. If damaged, replace it with a new one.

5. REMOVE VANE PUMP HOUSING REAR

(a) Remove the 4 bolts and vane pump housing rear from the vane pump housing front.

(b) Remove the O-ring from the vane pump housing front.

6. REMOVE PULLEY SHAFT SUB-ASSEMBLY

NOTICE:

Be careful not to drop or badly damage the pulley shaft. If damaged, replace it with a new one.

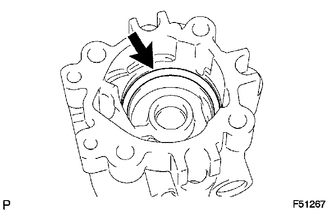

(a) Using a screwdriver, remove the snap ring from the pulley shaft.

(b) Remove the pulley shaft.

7. REMOVE VANE PUMP ROTOR

(a) Remove the 10 vane plates.

(b) Remove the vane pump rotor.

8. REMOVE VANE PUMP CAM RING

9. REMOVE VANE PUMP SIDE PLATE FRONT

(a) Remove the side plate from the vane pump housing front.

(b) Remove the O-ring from the side plate.

|

(c) Remove the O-ring from the vane pump housing front. |

|

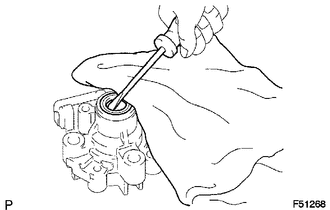

10. REMOVE VANE PUMP HOUSING OIL SEAL

(a) Using screwdriver, remove the oil seal.

NOTICE:

Be careful not to damage the vane pump housing front.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting

the cable from the negative (-) battery terminal.

Therefore, mak ...

Other materials:

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE MILLIMETER WAVE RADAR WIRE (w/ Toyota Safety Sense P)

Click here

2. REMOVE MILLIMETER WAVE RADAR SENSOR ASSEMBLY (w/ Toyota Safety Sense P)

Click here

3. REMOVE NO. 1 RADIATOR GRILLE GARNISH

(a) When Replacing the No. 1 Radiator Grille Garnish:

(1) Apply p ...

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEEL

2. DRAIN DIFFERENTIAL OIL

3. SEPARATE FRONT SPEED SENSOR

(a) Remove the bolt and separate the front speed sensor.

(b) Disengage the 2 clamps.

(c) Remove the bolt and separate the speed sensor wire harness from the steering

knuckle.

4. SEPARATE TIE ...

Cruise Control System Internal Failure (P057504,P057549)

DESCRIPTION

This DTC is stored when there is a malfunction in the ECM.

DTC No.

Detection Item

DTC Detection Condition

Trouble Area

MIL

P057504

Cruise Control System Internal Failure

While the dynamic rada ...