Toyota Tacoma (2015-2018) Service Manual: Removal

REMOVAL

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal.

Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work.

Click here .gif)

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

Click here .gif)

3. REMOVE NO. 1 ENGINE UNDER COVER SUB-ASSEMBLY

4. REMOVE FAN AND GENERATOR V BELT

Click here .gif)

5. DRAIN POWER STEERING FLUID

6. DISCONNECT PRESSURE FEED TUBE ASSEMBLY

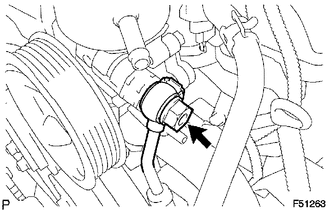

(a) Disengage the clip and disconnect the return hose.

|

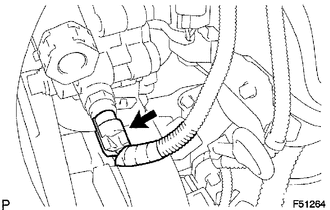

(b) Remove the union bolt, then disconnect the pressure feed tube. |

|

(c) Remove the gasket from the pressure feed tube.

7. REMOVE VANE PUMP

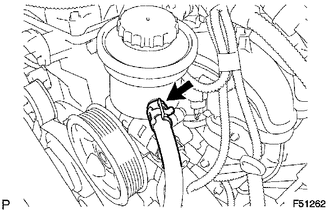

(a) Disconnect the oil pressure switch connector.

|

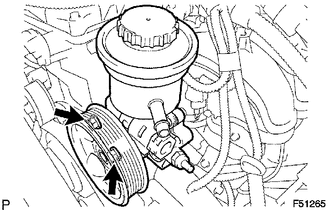

(b) Remove the 2 bolts and vane pump assembly. |

|

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. FIX VANE PUMP

(a) Using SST, fix the vane pump assembly in a vise.

SST: 09630-00014

09631-00132

NOTICE:

When using a vise, do not overtighten it.

2. REMOVE VANE PUMP ...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT OIL CLEARANCE

(a) Using a micrometer and caliper gauge, measure the oil seal clearance.

Standard clearance:

0.021 to 0.043 mm (0.0008 to 0.0017 in.)

Maximum cl ...

Other materials:

Operation Check

OPERATION CHECK

1. CHECK FUNCTION

(a) Check that the key reminder warning buzzer sounds.

(1) With the driver side door closed, insert the key into the ignition key cylinder

and then turn the key to LOCK or ACC.

(2) Check that the buzzer sounds intermittently when the driver side door is

open ...

A-TRAC Indicator Light does not Come ON

DESCRIPTION

The A-TRAC does not operate even if the A-TRAC switch is pressed under the following

conditions:

The TRAC or VSC system is faulty.

The temperature inside the hydraulic brake booster increases and the

A-TRAC operation is suspended.

WIRING DIAGRAM

Refer to A-TRAC ...

Front Occupant Classification Sensor RH Circuit Malfunction (B1781)

DESCRIPTION

The front occupant classification sensor RH circuit consists of the occupant

detection ECU and the front occupant classification sensor RH.

DTC B1781 is set when a malfunction is detected in the front occupant classification

sensor RH circuit.

DTC No.

DTC Det ...