Toyota Tacoma (2015-2018) Service Manual: Certification Ecu

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

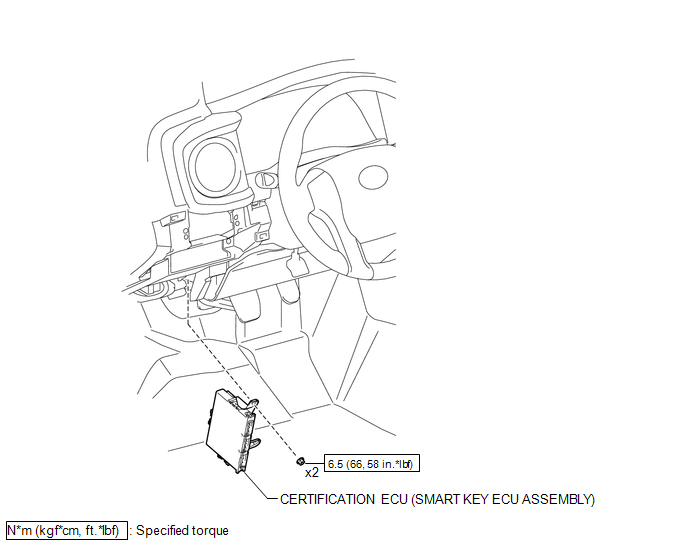

1. INSTALL CERTIFICATION ECU (SMART KEY ECU ASSEMBLY)

(a) Install the certification ECU (smart key ECU assembly) with the 2 nuts.

Torque:

6.5 N┬Ęm {66 kgf┬Ęcm, 58 in┬Ęlbf}

(b) Engage the clamp to install the wire harness.

(c) Connect the 3 connectors.

2. INSTALL INSTRUMENT PANEL LOWER FINISH PANEL SUB-ASSEMBLY

(See page .gif)

.gif) )

)

Removal

REMOVAL

PROCEDURE

1. REMOVE INSTRUMENT PANEL LOWER FINISH PANEL SUB-ASSEMBLY

(See page .gif)

.gif) )

)

2. REMOVE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY)

|

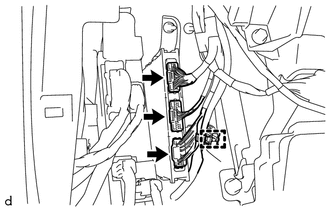

(a) Disconnect the 3 connectors. |

|

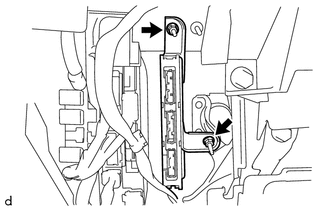

(b) Disengage the clamp to separate the wire harness.

|

(c) Remove the 2 nuts and certification ECU (smart key ECU assembly). |

|

Other materials:

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Dtc Check / Clear

DTC CHECK / CLEAR

1. CHECK DTC

(a) Check the DTCs.

(1) Turn the ignition switch off.

(2) Connect the Techstream to the DLC3.

(3) Turn the ignition switch to ON.

(4) Turn the Techstream on.

(5) Read the DTCs following the prompts on the Techstream screen. Enter the following

menus: Powertrai ...

No Answer-Back

DESCRIPTION

In some cases, wireless door lock control functions are normal but the hazard

warning light and/or wireless door lock buzzer answer-back function(s) does not

operate. In such cases, hazard warning light and wireless door lock buzzer signal

outputs from the main body ECU (multiplex ...