Toyota Tacoma (2015-2018) Service Manual: Brake

General Maintenance

GENERAL MAINTENANCE

PROCEDURE

1. INSPECT BRAKE LINE PIPES AND HOSES

HINT:

Work in a well-lighted area. Turn the front wheels fully to the right or left before beginning.

(a) Check all the brake lines and hoses for:

- Damage

- Wear

- Deformation

- Cracks

- Corrosion

- Leaks

- Bends

- Twists

(b) Check all the clamps for tightness and the connections for leakage.

(c) Check if the hoses and lines are not near sharp edges, moving parts and the exhaust system.

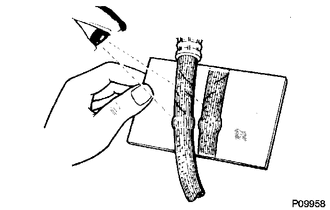

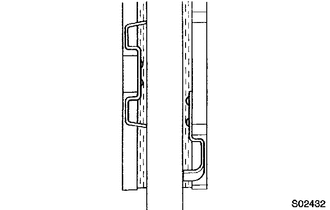

(d) Check if the lines are installed pass through the center of the grommets.

2. INSPECT FRONT BRAKE PADS AND DISCS

HINT:

- (See page

.gif) )

) - If a squealing or scraping noise is heard from the brake while driving, check the pad wear indicator.

- If there are traces of the indicator contacting the disc rotor, the disc pad should be replaced.

3. INSPECT REAR BRAKE DRUM

HINT:

See page .gif)

4. INSPECT BRAKE FLUID

Fluid:

SAE J1703 or FMVSS No. 116 DOT3

HINT:

- for Hydraulic Brake Booster (See page

.gif) )

) - for Vacuum Brake Booster (See page

.gif) )

)

Body

Body

General Maintenance

GENERAL MAINTENANCE

PROCEDURE

1. TIGHTEN BOLTS AND NUTS ON CHASSIS AND BODY

(a) Tighten the bolts and nuts on the chassis parts listed below, if necessary.

Front axle ...

Chassis

Chassis

General Maintenance

GENERAL MAINTENANCE

PROCEDURE

1. INSPECT STEERING LINKAGE

(a) Check the steering wheel free play (See page

).

(b) Check the steering linkage for looseness or damage.

(1) ...

Other materials:

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE REAR AXLE SHAFT SNAP RING

(a) Using a snap ring expander, remove the snap ring.

2. REMOVE REAR AXLE SHAFT

(a) Using SST and press, remove the rear axle shaft.

SST: 09521-25011

SST: 09521-25021

3. REMOVE REAR AXLE BEARING RETAINER INNER

(a) Remove the rear ...

Front Passenger Side Door ECU Communication Stop (B2322)

DESCRIPTION

This DTC is stored when LIN communication between the front power window regulator

motor assembly RH and main body ECU (multiplex network body ECU) stops for 10 seconds

or more.

DTC No.

DTC Detection Condition

Trouble Area

B2322

...

Voice Recognition Microphone Disconnected (B1579)

DESCRIPTION

The radio and display receiver assembly and telephone microphone assembly are

connected to each other using the microphone connection detection signal lines.

This DTC is stored when a microphone connection detection signal line is disconnected.

DTC Code

DTC Det ...