Toyota Tacoma (2015-2018) Service Manual: Wireless Charger Power Source Circuit

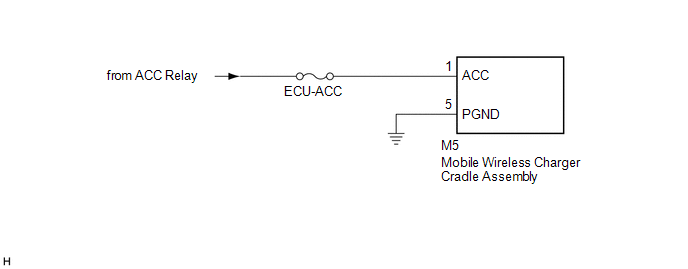

DESCRIPTION

This is the power source circuit to operate the mobile wireless charger cradle assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (MOBILE WIRELESS CHARGER CRADLE ASSEMBLY POWER SOURCE) |

(a) Disconnect the M5 mobile wireless charger cradle assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

M5-5 (PGND) - Body ground |

Always |

Below 1 Ω |

|

M5-1 (ACC) - Body ground |

Always |

10 kΩ or higher |

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

M5-1 (ACC) - M5-5 (PGND) |

Ignition switch ACC |

11 to 14 V |

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Terminals Of Ecu

Terminals Of Ecu

TERMINALS OF ECU

1. MOBILE WIRELESS CHARGER CRADLE ASSEMBLY

Tester Connection

Wiring Color

Terminal Description

Condition

Specified Condition ...

Main Switch Signal Circuit

Main Switch Signal Circuit

DESCRIPTION

When the wireless charger main switch (mobile wireless charger switch) is turned

on, this circuit sends an on signal to the mobile wireless charger cradle assembly

using the power sup ...

Other materials:

Open in One Side of Bus 3 Branch Line

DESCRIPTION

When the CAN bus main lines are normal (no open, short to ground, short to +B

or short between lines) and there is an ECU or sensor on the "Communication Bus

Check" screen that is indicated as not communicating or whose connection status

on the "Communication Bus Ch ...

Brake Warning Light Remains ON

DESCRIPTION

The skid control ECU (brake actuator assembly) is connected to the combination

meter assembly via CAN communication.

If any of the following is detected, the brake warning light remains on:

The skid control ECU (brake actuator assembly) connector is disconnected

from the ...

Multi-terrain Select Indicator Light does not Come ON

DESCRIPTION

When the transfer gear position is L4, the multi-terrain select indicator light

illuminates and control begins.

Under any of the following conditions, the multi-terrain select system does not

begin control and the multi-terrain select indicator light does not illuminate.

Th ...