Toyota Tacoma (2015-2018) Service Manual: Transponder Key Amplifier

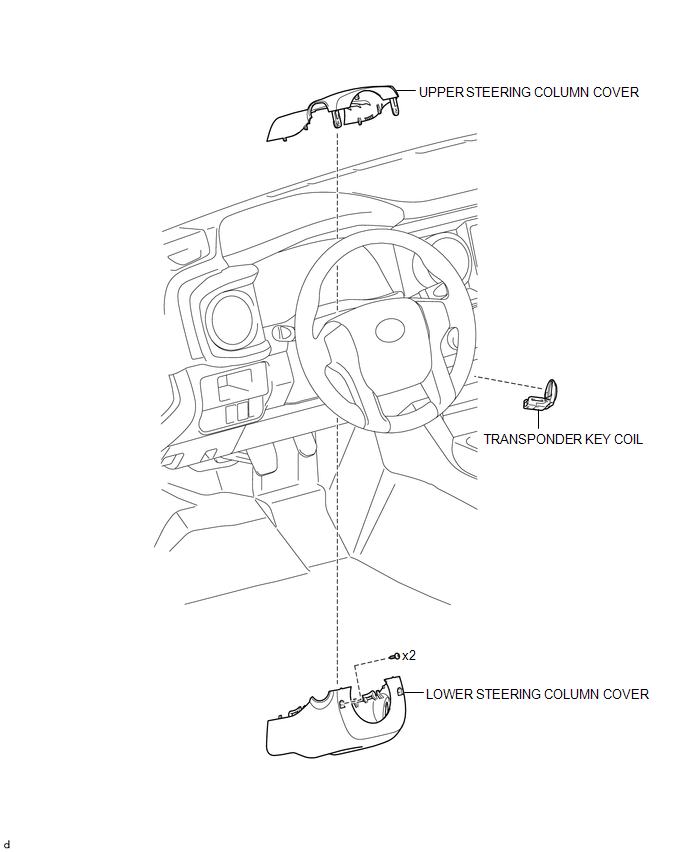

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL TRANSPONDER KEY COIL

|

(a) Engage the 2 claws to install the transponder key coil. |

|

(b) Connect the connector.

2. INSTALL UPPER STEERING COLUMN COVER

(See page .gif)

.gif) )

)

3. INSTALL LOWER STEERING COLUMN COVER

(See page .gif)

.gif) )

)

Removal

REMOVAL

PROCEDURE

1. REMOVE LOWER STEERING COLUMN COVER

(See page .gif)

.gif) )

)

2. REMOVE UPPER STEERING COLUMN COVER

(See page .gif)

.gif) )

)

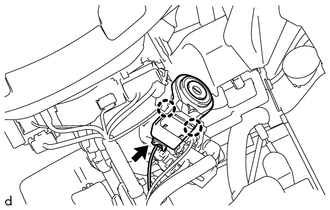

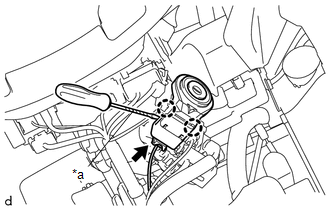

3. REMOVE TRANSPONDER KEY COIL

|

(a) Disconnect the connector. |

|

(b) Using a screwdriver with its tip wrapped in protective tape, disengage the 2 claws to remove the transponder key coil.

Text in Illustration|

*a |

Protective Tape |

Security Indicator Light Does not Blink

Security Indicator Light Does not Blink

DESCRIPTION

The transponder key ECU assembly blinks the security indicator light

when the immobiliser is set (no key is in the ignition key cylinder).

w/ Theft Deterrent System:

...

Transponder Key Ecu

Transponder Key Ecu

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL TRANSPONDER KEY ECU

(a) Engage the 2 guides to move the transponder key ECU in the direction

...

Other materials:

Operation Check

OPERATION CHECK

1. CHECK INTERMITTENT CONTROL FUNCTION (w/ Intermittent Time Adjustment Switch)

(a) Turn the ignition switch to ON.

(b) Turn the windshield wiper switch assembly to the INT position.

(c) Check that the intermittent operation interval can be adjusted from approximately

1.6 to 10 ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL OIL COOLER ASSEMBLY (w/ Air Cooled Transmission Oil Cooler)

(a) Install the 2 oil cooler brackets to the oil cooler assembly with the 2 bolts.

Torque:

5.5 N·m {56 kgf·cm, 49 in·lbf}

(b) Install the oil cooler assembly to the vehicle body with th ...

Fuel Tank Cap

Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL TANK CAP ASSEMBLY

(a) Check the appearance of the fuel tank cap assembly.

(1) Check that there is no deformation or damage to the fuel tank cap assembly

or fuel tank cap gasket.

*1

Fuel Tank Cap Gasket

If the ...