Toyota Tacoma (2015-2018) Service Manual: Transfer Case Rear Oil Seal

Components

COMPONENTS

ILLUSTRATION

Replacement

REPLACEMENT

PROCEDURE

1. DRAIN TRANSFER OIL

.gif)

2. REMOVE PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

(See page .gif) )

)

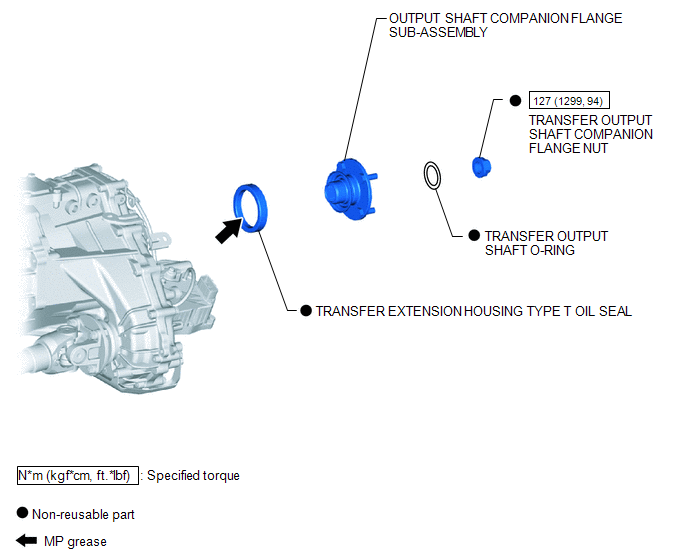

3. REMOVE OUTPUT SHAFT COMPANION FLANGE SUB-ASSEMBLY

.gif)

4. REMOVE TRANSFER EXTENSION HOUSING TYPE T OIL SEAL

|

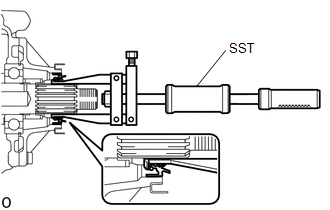

(a) Using SST, remove the transfer extension housing type T oil seal. SST: 09308-00010 NOTICE: Be careful not to damage the transfer extension housing type T oil seal and extension housing contact surface. |

|

5. INSTALL TRANSFER EXTENSION HOUSING TYPE T OIL SEAL

(a) Coat the lip of a new transfer extension housing type T oil seal with MP grease.

|

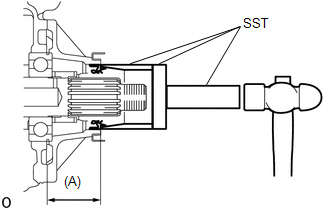

(b) Using SST and a hammer, install the transfer extension housing type T oil seal as shown in the illustration. SST: 09631-12090 SST: 09950-60010 09951-00600 SST: 09950-70010 09951-07100 Drive in depth (A): 48.5 to 49.5 mm (1.910 to 1.948 in.) NOTICE: Be careful not to damage the transfer extension housing type T oil seal. |

|

6. INSTALL OUTPUT SHAFT COMPANION FLANGE SUB-ASSEMBLY

.gif)

7. INSTALL PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

(See page .gif) )

)

8. ADD TRANSFER OIL

.gif)

9. CHECK FOR TRANSFER OIL LEAK

Transfer Case Front Oil Seal

Transfer Case Front Oil Seal

Components

COMPONENTS

ILLUSTRATION

Replacement

REPLACEMENT

PROCEDURE

1. DRAIN TRANSFER OIL

2. SUPPORT TRANSMISSION ASSEMBLY

3. REMOVE NO. 3 FRAME CROSSMEMBER SUB-ASSEMBLY

4. ...

Transfer Oil

Transfer Oil

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK TRANSFER OIL

(a) Remove the filler plug and gasket.

Text in Illustration

*1

Fill ...

Other materials:

Installation

INSTALLATION

PROCEDURE

1. INSTALL AIR CONDITIONING UNIT ASSEMBLY

(a) Temporary install the air conditioning unit assembly.

(b) Insert the bracket hook into the holes of the reinforcement bracket, and

temporary install the instrument panel reinforcement assembly.

(c) Install the instrument p ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT SEAT INNER BELT ASSEMBLY LH

(a) Check the resistance.

(1) Measure the resistance according to the value(s) in the table below.

Standard resistance:

Tester Connection

Condition

Specified C ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT NO. 1 ULTRASONIC SENSOR

(a) Measure the resistance according to the value(s) in the table below.

Text in Illustration

*a

Component without harness connected:

(No. 1 Ultrasonic Sensor)

Standar ...