Toyota Tacoma (2015-2018) Service Manual: Taillight Relay Circuit

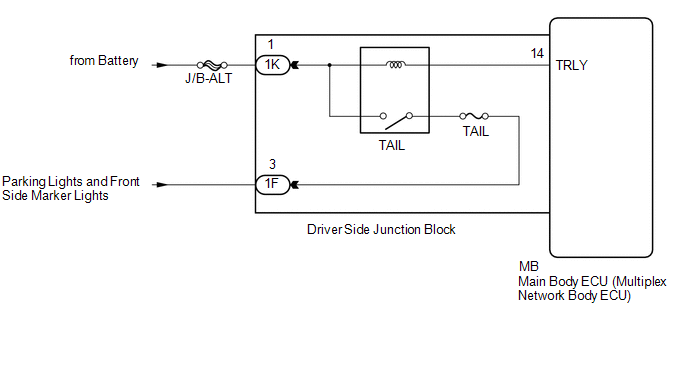

DESCRIPTION

The main body ECU (multiplex network body ECU) controls the operation of the TAIL relay.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

- If the main body ECU (multiplex network body ECU) is replaced, refer

to Registration (See page

.gif) ).*1

).*1

- *1: w/ Smart Key System

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM (TAILLIGHT RELAY) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Main Body / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Main Body|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Taillight Relay |

Taillight relay |

ON/OFF |

- |

OK:

Taillight relay operates. (Taillights illuminate.)

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

2. |

CHECK HARNESS AND CONNECTOR (BATTERY - DRIVER SIDE JUNCTION BLOCK) |

(a) Disconnect the 1K driver side junction block connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1K-1 - Body ground |

Always |

11 to 14 V |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

INSPECT DRIVER SIDE JUNCTION BLOCK |

(a) Remove the driver side junction block (See page

.gif) ).

).

(b) Remove the main body ECU (multiplex network body ECU) from the driver side junction block.

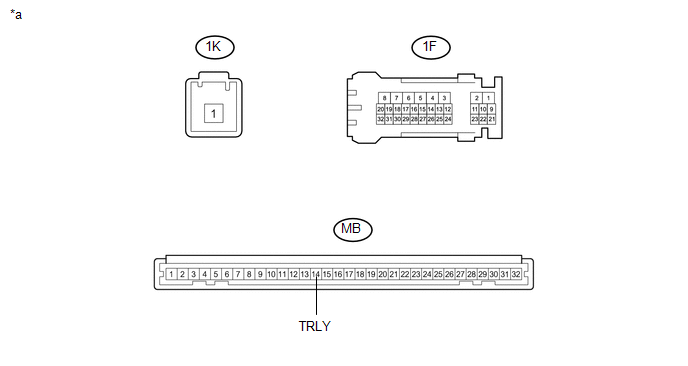

Text in Illustration

Text in Illustration

|

*a |

Component without harness connected (Driver Side Junction Block) |

- |

- |

(c) Connect a positive (+) lead from the battery to terminal 1K-1.

(d) Connect a negative (-) lead from the battery to terminal MB-14 (TRLY).

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1F-3 - Battery negative terminal |

Always |

11 to 14 V |

| OK | .gif) |

REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

| NG | .gif) |

REPLACE DRIVER SIDE JUNCTION BLOCK |

Engine Switch Illumination Circuit

Engine Switch Illumination Circuit

DESCRIPTION

The illuminated entry system controls the engine switch illumination.

WIRING DIAGRAM

PROCEDURE

1.

READ VALUE USING TECHSTREAM (POWER/ENGINE SW LIGHT)

...

Cargo Light Circuit

Cargo Light Circuit

DESCRIPTION

The main body ECU (multiplex network body ECU) receives a cargo light information

signal from the deck light switch assembly and door courtesy light switch, and illuminates

the cargo ...

Other materials:

Transmission Range Sensor "A" Circuit Open (P070513,P070562)

DESCRIPTION

The park/neutral position switch detects the shift lever position and sends signals

to the ECM.

DTC No.

DTC Detection Condition

Trouble Area

SAE

P070513

All of the following signals are OFF simultaneously for 60 ...

Installation

INSTALLATION

PROCEDURE

1. REMOVE MONOLITHIC CONVERTER PROTECTOR

(a) Install the upper monolithic converter protector and lower monolithic converter

protector with the 2 bolts and 2 nuts.

Torque:

11 N·m {107 kgf·cm, 8 ft·lbf}

(b) Install the clamp with the bolt as shown in the ...

Open in Driver Side Electrical Antenna Circuit (B27A1)

DESCRIPTION

The certification ECU (smart key ECU assembly) generates a request signal and

transmits the signal to the front door outside handle assembly LH [electrical key

antenna] at intervals of 0.25 seconds. For the front door outside handle assembly

LH [electrical key antenna] to detect w ...

.gif)