Toyota Tacoma (2015-2018) Service Manual: Security Horn Assembly

Components

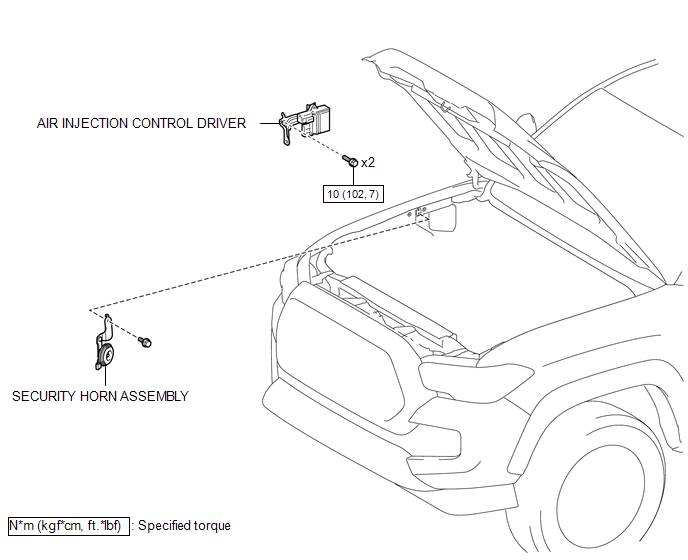

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

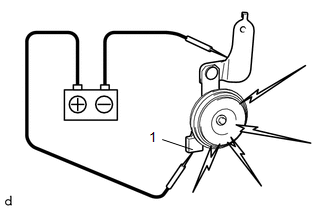

1. INSPECT SECURITY HORN ASSEMBLY

|

(a) Check the operation. (1) Apply battery voltage and check operation of the security horn assembly. OK:

If the result is not as specified, replace the security horn assembly. |

|

Removal

REMOVAL

PROCEDURE

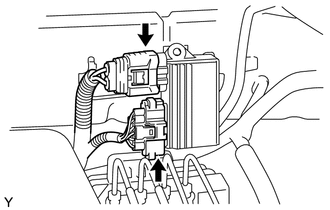

1. REMOVE AIR INJECTION CONTROL DRIVER (for 2TR-FE)

|

(a) Disconnect the 2 connectors. |

|

|

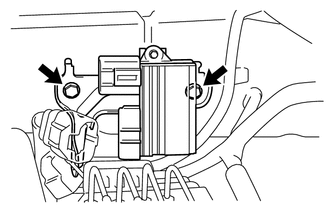

(b) Remove the 2 bolts and air injection control driver. |

|

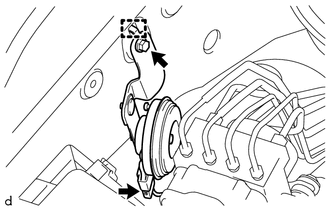

2. REMOVE SECURITY HORN ASSEMBLY

|

(a) Disconnect the connector. |

|

(b) Remove the bolt.

(c) Disengage the guide to remove the security horn assembly.

Installation

INSTALLATION

PROCEDURE

1. INSTALL SECURITY HORN ASSEMBLY

(a) Engage the guide to install the security horn assembly.

(b) Install the bolt.

(c) Connect the connector.

2. INSTALL AIR INJECTION CONTROL DRIVER (for 2TR-FE)

(a) Install the air injection control driver with the 2 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(b) Connect the 2 connectors.

Engine Hood Courtesy Switch

Engine Hood Courtesy Switch

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT HOOD COURTESY SWITCH (HOOD LOCK ASSEMBLY)

(a) Check the resistance.

(1) Measure the resistance ac ...

Other materials:

Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL INJECTOR ASSEMBLY

NOTICE:

This inspection aims at inspecting the fuel injectors for opens or shorts, because

the fuel injectors of this vehicle are a high-pressure type and cannot be inspected

for fuel injection volume.

(a) Measure the resistance accordi ...

Rear Seat Inner Belt Assembly(for Access Cab)

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE REAR NO. 1 SEAT INNER BELT ASSEMBLY

(a) Open the 2 anchor covers.

(b) Loosen the 2 bolts to remove the 2 rear No. 1 seat inner belt assemblies.

Installation

I ...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL REAR AXLE HUB BOLT

(a) Install a new deflector gasket and deflector onto the rear axle shaft.

HINT:

Align the 2 notches.

(b) Install the 6 bolts through the axle hub.

...