Toyota Tacoma (2015-2018) Service Manual: Replacement

REPLACEMENT

PROCEDURE

1. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

(a) Start up the engine.

(b) Turn the A/C switch to ON.

(c) Operate the cooler compressor with an engine speed of approximately 1,000 rpm for 5 to 6 minutes to circulate the refrigerant and collect the compressor oil remaining in each component into the cooler compressor.

(d) Stop the engine.

(e) Recover the refrigerant from the A/C system using a refrigerant recovery unit.

2. CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT

(a) Perform vacuum purging using a vacuum pump.

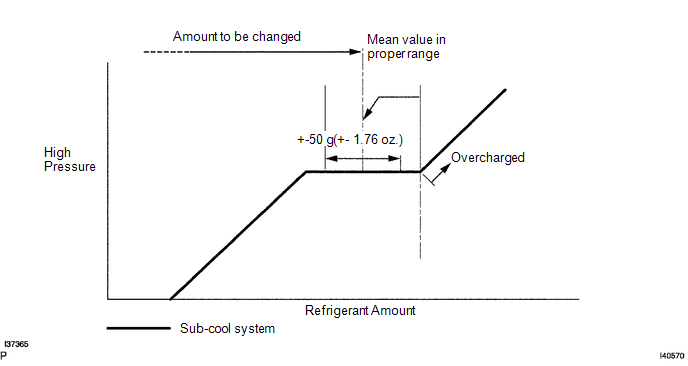

(b) Charge refrigerant HFC-134a (R134a).

Standard:

570 to 630 g (20.10 to 22.22 oz.)

SST: 09985-20010

09985-02010

09985-02050

09985-02060

09985-02070

09985-02080

09985-02090

09985-02110

09985-02130

09985-02140

09985-02150

NOTICE:

Do not start the engine before charging it with refrigerant as the cooler compressor does not work properly without any refrigerant. This could cause the compressor to overheat.

3. WARM UP ENGINE

NOTICE:

Warm up the engine at less than 2,000 rpm for 2 minutes or more after charging it with refrigerant.

4. INSPECT FOR REFRIGERANT LEAK

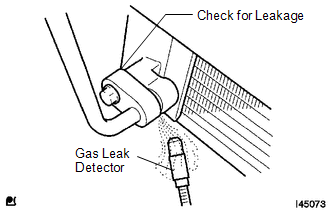

(a) After recharging the refrigerant gas, check for refrigerant gas leakage using a halogen leak detector.

(b) Perform the operation under these conditions:

- Stop the engine.

- Secure good ventilation (the gas leak detector may react to volatile gases other than refrigerant, such as evaporated gasoline or exhaust gas).

- Repeat the test 2 or 3 times.

- Make sure that some refrigerant remains in the refrigeration system.

When compressor is off: approximately 392 to 588 kPa (4 to 6 kgf/cm2, 57 to 85 psi)

|

(c) Using a gas leak detector, check the refrigerant line for leakage. |

|

|

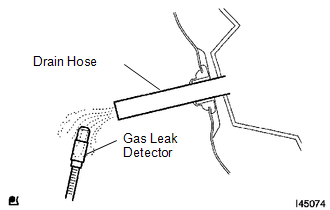

(d) Bring the gas leak detector close to the drain hose with the detector power off. HINT:

HINT: If such reaction is unavoidable, the vehicle must be lifted up. |

|

(e) If a gas leak is not detected from the drain hose, remove the blower motor control from the cooling unit. Insert the gas leak detector sensor into the unit and perform the test.

(f) Disconnect the pressure switch connector and leave it for approximately 20 minutes. Bring the gas leak detector close to the pressure switch and perform the test.

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT REFRIGERANT PRESSURE WITH MANIFOLD GAUGE SET

(a) This is a method to specify trouble areas by using a manifold gauge set.

Read the manifold gauge pressu ...

Other materials:

If a warning light turns on or a warning buzzer sounds

Calmly perform the following actions if any of the warning lights turn on

or flash. If a light turns on or flashes, but then turns off, this does not necessarily

indicate a malfunction in the system.

Stop the vehicle immediately. Continuing to drive the vehicle may be dangerous.

The following ...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Troubleshooting of the theft deterrent system is based on the premise

that the power door lock control system, wireless door lock control system*1

and smart key system*2 are operating normally. Accordingly, before troubleshooting

the theft deterrent ...

Installation

INSTALLATION

PROCEDURE

1. SET NO. 1 CYLINDER TO TDC/COMPRESSION

2. INSTALL CAMSHAFT TIMING GEAR BOLT

NOTICE:

There are different types of camshaft timing gear bolts. Make sure to check the

identification mark to determine the tightening torque.

*a

Identification Ma ...