Toyota Tacoma (2015-2018) Service Manual: Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL COMPRESSOR PICK UP SENSOR

|

(a) Install the compressor pick up sensor with the 3 screws. |

|

(b) Engage the clamp.

2. INSTALL MAGNET CLUTCH ASSEMBLY

(a) Secure the cooler compressor assembly in a vise between aluminum plates.

(b) Install the magnet clutch stator with the parts shown in the illustration.

|

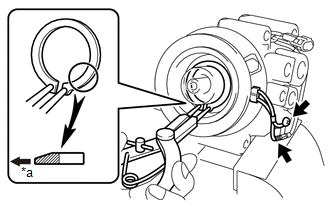

(c) Using a snap ring expander, install a new snap ring with the chamfered side facing up. |

|

(d) Connect the connector.

(e) Install the screw.

|

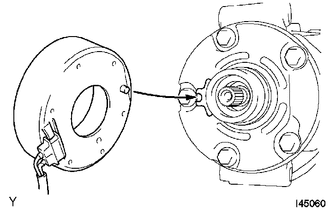

(f) Using a snap ring expander, install the magnet clutch rotor and a new snap ring with the chamfered side facing up. Text in Illustration

NOTICE: Do not damage the seal cover of the bearing when installing the snap ring. |

|

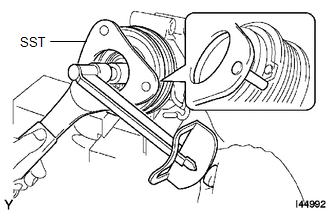

(g) Install the compressor spacer and magnet clutch hub.

NOTICE:

Do not change the combination of the compressor spacer used before disassembly.

|

(h) Using SST, hold the magnet clutch hub and install the bolt. SST: 09985-00260 Torque: 13.5 N·m {138 kgf·cm, 10 ft·lbf} NOTICE: Make sure that there is no foreign matter or oil on the compressor shaft, bolt, and clutch hub. |

|

3. INSTALL PRESSURE RELIEF VALVE

(a) Apply sufficient compressor oil to a new O-ring and fitting surface of the pressure relief valve.

Compressor oil:

PSD1 or equivalent

(b) Install a new O-ring onto the pressure relief valve.

(c) Install the pressure relief valve.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

4. INSPECT MAGNET CLUTCH CLEARANCE

|

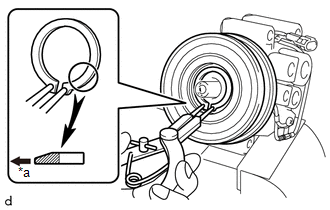

(a) Secure the cooler compressor assembly in a vise between aluminum plates. Text in Illustration

|

|

(b) Set the dial indicator to the magnet clutch hub.

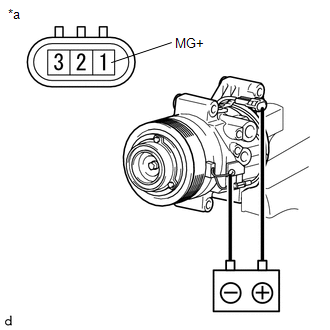

(c) Connect the battery positive lead to terminal 1 (MG+) of the magnet clutch connector and the negative lead to the ground wire. Turn the magnet clutch on and off and measure the clearance.

Standard clearance:

0.30 to 0.60 mm (0.012 to 0.024 in.)

If the measured value is not within the standard clearance, remove the magnet clutch hub and adjust the clearance using compressor spacer to obtain the standard clearance.

Compressor spacer thickness:

0.2 mm (0.008 in.)

0.3 mm (0.012 in.)

0.5 mm (0.020 in.)

NOTICE:

Adjustment should be performed with 3 or less magnet clutch washers.

(d) Remove the compressor and magnetic clutch from the vise.

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT MAGNET CLUTCH ASSEMBLY

(a) Inspect the magnet clutch assembly.

Text in Illustration

*a

Component without harness c ...

Installation

Installation

INSTALLATION

PROCEDURE

1. ADJUST COMPRESSOR OIL

(a) for HFC-134a (R134a):

(1) When replacing the compressor and magnetic clutch with new ones, after gradually

discharging the refrigerant gas fro ...

Other materials:

Steering Angle Sensor (C1A47)

DESCRIPTION

The forward recognition camera receives steering angle information from the spiral

cable with sensor sub-assembly. If the forward recognition camera detects a spiral

cable with sensor sub-assembly, DTC C1A47 is stored.

DTC No.

Detection Item

DTC Det ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT FRONT WIPER MOTOR (for Driver Side)

Text in Illustration

*a

Matchmark

(a) Check the stop (park) position.

(b) Operate the windshield wiper motor assembly.

(c) Stop the windshield wiper motor assembly operation.

(d) Ch ...

Lost Communication with ECM (U0100,U0142,U0155)

DESCRIPTION

DTC No.

DTC Detecting Condition

Trouble Area

U0100

No communication with ECM

CAN communication system

ECM

U0142

No communication with main body ECU

...

.png)