Toyota Tacoma (2015-2018) Service Manual: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK FUEL PUMP OPERATION AND INSPECT FOR FUEL LEAK

(a) Connect the Techstream to the DLC3.

(1) Turn the ignition switch to ON.

NOTICE:

Do not start the engine.

(2) Turn the Techstream on.

(3) Enter the following menus: Powertrain / Engine / Active Test / Control the Fuel Pump / Speed.

(b) Check the fuel pump operation.

(1) Check for pressure in the fuel inlet tube from the fuel line. Check that the sound of fuel flowing in the fuel tank can be heard.

If there is no sound, check the fuel pump, ECM and wiring connector.

(c) Inspect for fuel leaks.

(1) Check that there are no fuel leaks anywhere in the system after performing maintenance.

If there is a fuel leak, repair or replace parts as necessary.

2. CHECK FUEL PRESSURE

(a) Check the battery voltage.

Click here .gif)

(b) Discharge the fuel system pressure.

Click here .gif)

(c) Disconnect the cable from the negative (-) battery terminal.

NOTICE:

- After turning the ignition switch off, waiting time may be required

before disconnecting the cable from the battery terminal. Therefore, make

sure to read the disconnecting the cable from the battery terminal notice

before proceeding with work.

Click here

.gif)

- When disconnecting the cable, some systems need to be initialized after

the cable is reconnected.

Click here

.gif)

(d) Disconnect the fuel tube sub-assembly (Direct injection side).

Click here .gif)

(e) Disconnect the fuel tube sub-assembly (Port injection side).

Click here .gif)

|

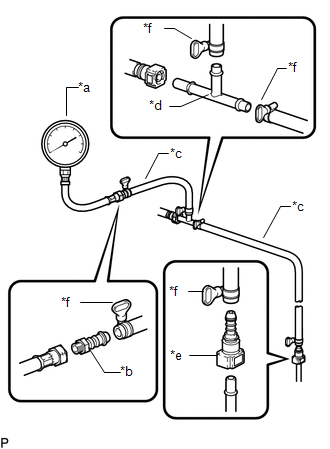

(f) Install SST (pressure gauge) as shown in the illustration. SST: 09268-45100 09268-41250 09268-41260 09268-41270 95336-08070 SST: 09268-31014 09268-41500 09268-41700 Text in Illustration

|

|

(g) Wipe off any gasoline.

(h) Reconnect the cable to the negative (-) battery terminal.

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

Click here .gif)

(i) Operate the fuel pump.

(1) Connect the Techstream to the DLC3.

(2) Turn the ignition switch to ON.

NOTICE:

Do not start the engine.

(3) Turn the Techstream on.

(4) Enter the following menus: Powertrain / Engine / Active Test / Control the Fuel Pump / Speed.

(j) Measure the fuel pressure.

Standard fuel pressure:

196 to 588 kPa (2.0 to 6.0 kgf/cm2, 28 to 85 psi)

If the fuel pressure is higher than the specification, replace the fuel main valve assembly.

If the pressure is less than the specification, check the fuel hoses, connections, fuel filter assembly, fuel main valve assembly, and fuel pump.

(k) Start the engine.

(l) Measure the fuel pressure at idle.

Standard fuel pressure:

196 to 588 kPa (2.0 to 6.0 kgf/cm2, 28 to 85 psi)

If the pressure is not as specified, check the fuel pump, fuel main valve assembly and fuel injector assembly.

(m) Stop the engine.

(n) Check that the fuel pressure remains as specified for 5 minutes after the engine has stopped.

Standard fuel pressure:

147 kPa (1.5 kgf/cm2, 21 psi) or more

If the pressure is not as specified, check the fuel pump, fuel main valve assembly or fuel injector assembly.

(o) After checking the fuel pressure, disconnect the cable from the negative (-) battery terminal and carefully remove SST and the fuel tube connector to prevent fuel from spilling.

(p) Reconnect the fuel tube sub-assembly.

Click here .gif)

(q) Inspect for fuel leaks (Step 1).

3. CHECK FUEL PRESSURE (for High Pressure)

(a) Connect the Techstream to the DLC3.

(1) Turn the ignition switch to ON.

(2) Turn the Techstream on.

(b) Start and warm up the engine.

(c) Run the engine at idle.

(d) Enter the following menus: Powertrain / Engine / Data List / Fuel Press.

(e) Check the high pressure side fuel pressure.

Standard fuel pressure:

1800 to 2800 kPa (18.4 to 28.6 kgf/cm2, 261 to 406 psi)

If the pressure is not as specified, check the fuel pump, fuel pump assembly, fuel pressure sensor and wire harness.

(f) Stop the engine.

System Diagram

System Diagram

SYSTEM DIAGRAM

1. HIGH PRESSURE SIDE FUEL SYSTEM WIRING DIAGRAM

2. LOW PRESSURE SIDE FUEL SYSTEM WIRING DIAGRAM

...

Fuel Tank

Fuel Tank

...

Other materials:

Installation

INSTALLATION

PROCEDURE

1. INSTALL INSTRUMENT PANEL PASSENGER AIRBAG ASSEMBLY WITHOUT DOOR

(a) Engage the 3 hooks (B).

Text in Illustration

*a

Hooks (A)

*b

Hooks (B)

...

Illumination Circuit

DESCRIPTION

Power is supplied to the navigation receiver assembly and steering pad switch

assembly illumination when the light control switch is in the TAIL or HEAD position.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

The vehicle is equipped with a Supplemental Restraint System ...

Radio Antenna Cord

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE INSTRUMENT PANEL SUB-ASSEMBLY

(See page )

2. REMOVE ANTENNA CORD SUB-ASSEMBLY

(a) Disengage the 4 clamps to remove the antenna cord sub-assembly.

Installation

INSTALLATION

PROCEDURE

1. INSTALL ANTENNA COR ...