Toyota Tacoma (2015-2018) Service Manual: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

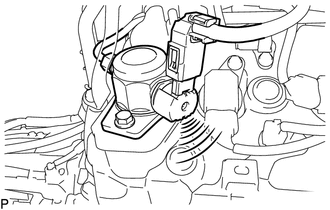

1. CHECK FUEL PUMP ASSEMBLY OPERATION

(a) Check fuel pressure.

(1) Connect the Techstream to the DLC3.

(2) Start the engine.

(3) Turn the Techstream on.

(4) Enter the following menus: Powertrain / Engine / Active Test / Control the Target Fuel Pressure.

(5) Check that the fuel pressure fluctuates when the target fuel pressure changes.

HINT:

The target fuel pressure operation lowers the target fuel pressure by 12.5% or increases the target fuel pressure by 25%.

Standard:

Fuel pressure fluctuates in accordance with the Techstream operation.

If the result is not as specified, replace the fuel delivery pipe sub-assembly (fuel pressure sensor).

(b) Check operating sound.

(1) Remove the V-bank cover sub-assembly (See page

.gif)

.gif) ).

).

(2) Start the engine.

|

(3) Using a sound scope, check the operating sound of the pump. If no sound can be heard, check the fuel pump, wire harness and ECM. |

|

(4) Stop the engine.

(5) Install the V-bank cover sub-assembly (See page

.gif)

.gif) ).

).

Components

Components

COMPONENTS

ILLUSTRATION

*1

FUEL PUMP ASSEMBLY

*2

FUEL PUMP LIFTER ASSEMBLY

*3

FUEL PUMP LIFTER GUIDE

*4

...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE INTAKE MANIFOLD

(See page )

2. REMOVE WIRE HARNESS CLAMP BRACKET

(a) Remove the 2 bolts and wire harness clamp bracket.

...

Other materials:

Starter Relay

Inspection

INSPECTION

PROCEDURE

1. INSPECT STARTER RELAY

(a) Check the resistance.

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection

Connection

Specified Condition

3 - 5

...

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE TAIL GATE PROTECTOR

(See page )

2. REMOVE TAIL GATE SERVICE HOLE COVER

(a) Using a T30 "TORX" socket wrench, remove the 8 screws and tail gate

service hole cover.

3. REMOVE REAR TELEVISION CAMER ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT OIL CLEARANCE

(a) Using a micrometer and caliper gauge, measure the oil seal clearance.

Standard clearance:

0.021 to 0.043 mm (0.0008 to 0.0017 in.)

Maximum clearance:

0.07 mm (0.0028 in.)

If it is greater than the maximum, replace the vane pump assembly.

...