Toyota Tacoma (2015-2018) Service Manual: Components

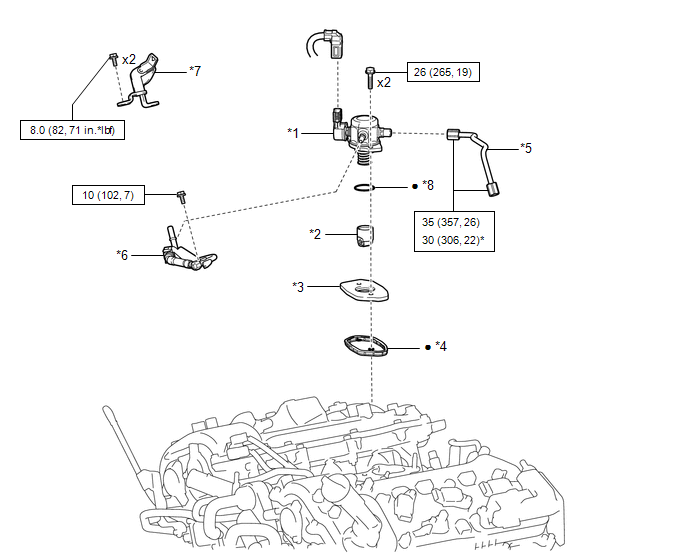

COMPONENTS

ILLUSTRATION

|

*1 |

FUEL PUMP ASSEMBLY |

*2 |

FUEL PUMP LIFTER ASSEMBLY |

|

*3 |

FUEL PUMP LIFTER GUIDE |

*4 |

FUEL PUMP SPACER GASKET |

|

*5 |

NO. 1 FUEL PIPE SUB-ASSEMBLY |

*6 |

FUEL TUBE SUB-ASSEMBLY |

|

*7 |

WIRE HARNESS CLAMP BRACKET |

*8 |

O-RING |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

* |

For use with union nut wrench |

|

â—Ź |

Non-reusable part |

- |

- |

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK FUEL PUMP ASSEMBLY OPERATION

(a) Check fuel pressure.

(1) Connect the Techstream to the DLC3.

(2) Start the engine.

(3) Turn the Techstream on.

(4) Ente ...

Other materials:

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" column of the

table. Check each sy ...

Components

COMPONENTS

ILLUSTRATION

*1

COWL TOP VENTILATOR LOUVER SUB-ASSEMBLY

*2

FRONT FENDER UPPER PROTECTOR LH

*3

FRONT FENDER UPPER PROTECTOR RH

*4

FRONT WIPER ARM HEAD CAP

*5

WINDSH ...

Lost Communication with Yaw Rate Sensor Module (U0123,U0126,U0129,U0142,U0155)

DESCRIPTION

These DTCs are output when a communication malfunction occurs between the sensors

and ECUs.

DTC No.

Detection Item

DTC Detection Condition

Trouble Area

U0123

Lost Communication with Yaw Rate Sensor Module

...