Toyota Tacoma (2015-2018) Service Manual: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

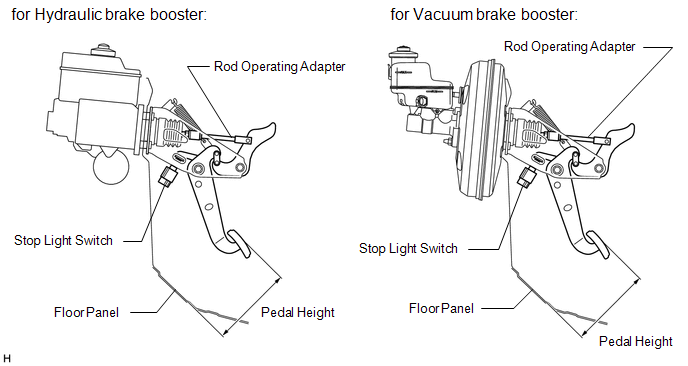

1. INSPECT BRAKE PEDAL HEIGHT

(a) Check the brake pedal height.

Pedal height from dash panel:

|

Type |

Pedal Height |

|---|---|

|

Automatic transmission |

164.4 to 174.4 mm (6.473 to 6.866 in.) |

|

Manual transmission |

160.5 to 170.5 mm (6.319 to 6.712 in.) |

NOTICE:

Do not adjust the pedal height. Doing so by changing the push rod length will structurally change the pedal ratio.

If the pedal height is incorrect, adjust the rod operating adapter length.

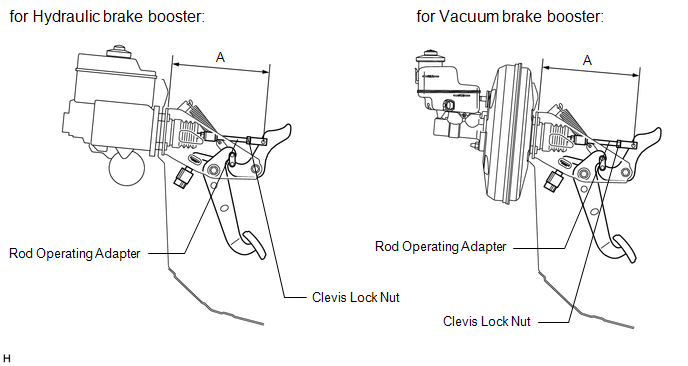

(b) Adjust the rod operating adapter length.

(1) Remove the clip and clevis pin.

(2) Loosen the clevis lock nut.

(3) Adjust the rod operating adapter length by turning the pedal push rod clevis.

Rod operating adapter length A:

for Hydraulic brake booster

214 to 224 mm (8.425 to 8.818 in.)

for Vacuum brake booster

213 to 223 mm (8.386 to 8.780 in.)

(4) Tighten the clevis lock nut.

Torque:

26 N·m {260 kgf·cm, 19 ft·lbf}

(5) Install the clip and clevis pin.

- If the pedal height is incorrect even when the rod operating adapter is adjusted, check that there is no damage in the brake pedal, brake pedal lever, brake pedal bracket or dash panel.

- Even if there is damage, there is no problem if the reserve distance is within the standard value.

- If necessary, replace the parts.

2. INSPECT AND ADJUST STOP LIGHT SWITCH ASSEMBLY

HINT:

If the pedal height is incorrect, check and adjust the stop light switch.

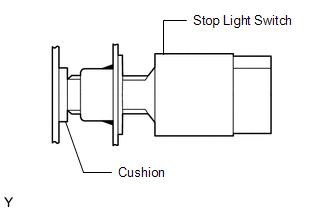

(a) Disconnect the stop light switch connector from the stop light switch.

(b) Turn the stop light switch counterclockwise, and remove the stop light switch.

|

(c) Insert the stop light switch until the body comes into contact with the cushion. NOTICE:

|

|

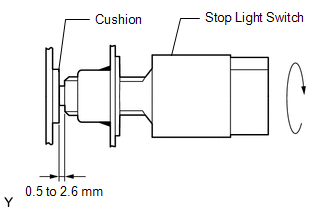

|

(d) Make a quarter turn clockwise to install the stop light switch. NOTICE: The turning torque for installing the stop light switch: Torque: 1.5 N·m {15 kgf·cm, 13 in·lbf} or less |

|

(e) Check the protrusion of the rod.

Protrusion of the rod:

0.5 to 2.6 mm (0.020 to 0.102 in.)

(f) Connect the stop light switch connector to the stop light switch.

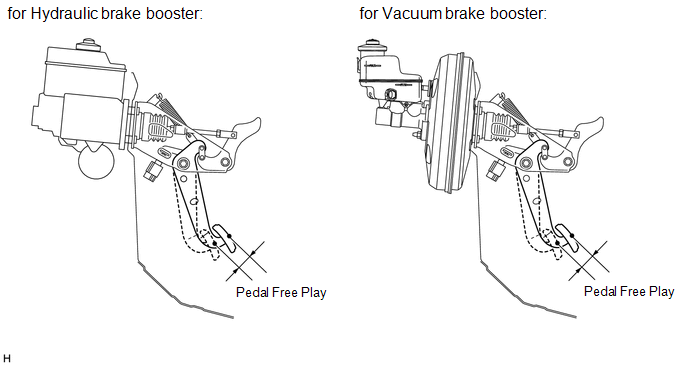

3. INSPECT PEDAL FREE PLAY

(a) Stop the engine and depress the brake pedal several times until there is no more vacuum left in the booster.

(b) Push in the pedal until the beginning of the resistance is felt. Measure the distance as shown.

Pedal free play:

1 to 6 mm (0.04 to 0.24 in.)

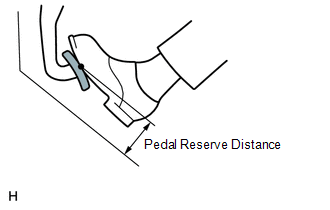

4. INSPECT PEDAL RESERVE DISTANCE

(a) Release the parking brake pedal.

With the engine running, depress the pedal and measure the pedal reserve distance as shown.

Pedal reserve distance from asphalt sheet at 490 N (50 kgf, 110.2 lbf):

More than 55 mm (2.17 in.)

If incorrect, troubleshoot the brake system.

Components

Components

COMPONENTS

ILLUSTRATION

...

Removal

Removal

REMOVAL

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting

the cable from the negative (-) battery terminal. Therefore, make ...

Other materials:

Cruise control

Use the cruise control to maintain a set speed without depressing the accelerator

pedal.

Indicator

Cruise control switch

■ Setting the vehicle speed

Press the ON-OFF button to activate the cruise control.

Cruise control indicator will come on.

Press the button again to deactivate ...

Removal

REMOVAL

PROCEDURE

1. REMOVE INSTRUMENT PANEL LOWER FINISH PANEL SUB-ASSEMBLY

(See page )

2. REMOVE DRIVER SIDE JUNCTION BLOCK

(a) Disconnect the 5 connectors on the front side.

(b) Remove the 2 nuts to separate the driver side j ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT POWER WINDOW REGULATOR MOTOR ASSEMBLY (for Power Slide Type)

*a

Component without harness connected

(Power Window Regulator Motor Assembly)

*b

Clockwise

*c

Counterclockwise

...