Toyota Tacoma (2015-2018) Service Manual: Installation

INSTALLATION

PROCEDURE

1. INSTALL WINDSHIELD WIPER MOTOR ASSEMBLY

|

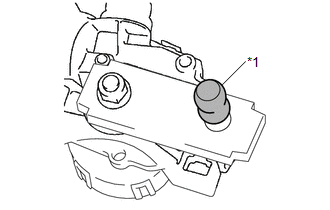

(a) Apply MP grease to the crank arm pivot of the windshield wiper motor assembly. Text in Illustration

|

|

(b) Using a T30 "TORX" socket wrench, install the front wiper motor assembly with the 2 bolts.

Torque:

7.5 N·m {76 kgf·cm, 66 in·lbf}

|

(c) Install the 2 rods to the crank arm pivot of the windshield wiper motor assembly. |

|

2. INSTALL WINDSHIELD WIPER MOTOR AND LINK

|

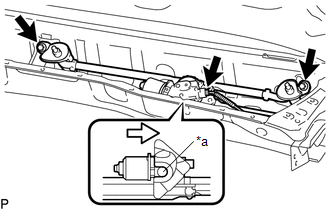

(a) Engage the motor grommet and temporarily install the windshield wiper motor and link as shown in the illustration. Text in Illustration

|

|

(b) Install the windshield wiper motor and link with the 2 bolts.

Torque:

5.5 N·m {56 kgf·cm, 49 in·lbf}

(c) Connect the connector.

3. INSTALL COWL TOP VENTILATOR LOUVER SUB-ASSEMBLY

(a) Engage the 9 guides to install the cowl top ventilator louver sub-assembly.

(b) Engage the guide and 6 claws.

4. INSTALL FRONT FENDER UPPER PROTECTOR LH

(a) Engage the 3 clips to install the front fender upper protector LH.

(b) Install the clip.

5. INSTALL FRONT FENDER UPPER PROTECTOR RH

HINT:

Use the same procedure as for the LH side.

6. INSTALL WINDSHIELD WIPER ARM AND BLADE ASSEMBLY LH

(a) When reusing the windshield wiper arm and blade assembly LH:

|

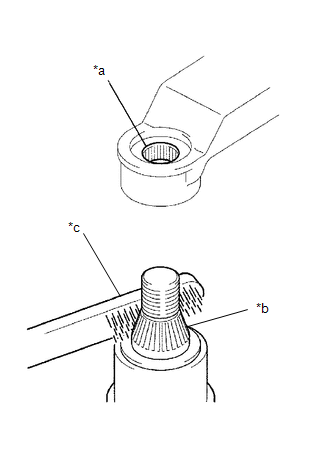

(1) Clean the wiper arm serrations to remove any burrs, dirt, etc. Text in Illustration

NOTICE: Do not grind down the wiper arm serrations. |

|

(2) Clean the wiper pivot serrations with a wire brush.

NOTICE:

Do not grind down the wiper pivot serrations.

(3) Operate the front wiper motor and then stop the front wiper motor in the automatic stop (park) position.

|

(b) Install the windshield wiper arm and blade assembly LH to the position with the nut as shown in the illustration. Torque: 22 N·m {224 kgf·cm, 16 ft·lbf} Text in Illustration

HINT: Hold the windshield wiper arm and blade assembly LH by hand while tightening the nut. |

|

(c) Operate the front wipers while spraying washer fluid on the windshield glass. Make sure that the front wipers function properly and there is no interference with the vehicle body.

(d) Check the automatic stop (park) position after lifting the wiper blade 2 times as shown in the illustration.

7. INSTALL WINDSHIELD WIPER ARM AND BLADE ASSEMBLY RH

(a) When reusing the windshield wiper arm and blade assembly RH:

|

(1) Clean the wiper arm serrations to remove any burrs, dirt, etc. Text in Illustration

NOTICE: Do not grind down the wiper arm serrations. |

|

(2) Clean the wiper pivot serrations with a wire brush.

NOTICE:

Do not grind down the wiper pivot serrations.

(3) Operate the front wiper motor and then stop the front wiper motor in the automatic stop (park) position.

|

(b) Install the windshield wiper arm and blade assembly RH to the position with the nut as shown in the illustration. Torque: 22 N·m {224 kgf·cm, 16 ft·lbf} Text in Illustration

HINT: Hold the windshield wiper arm and blade assembly RH by hand while tightening the nut. |

|

(c) Operate the front wipers while spraying washer fluid on the windshield glass. Make sure that the front wipers function properly and there is no interference with the vehicle body.

(d) Check the automatic stop (park) position after lifting the wiper blade 2 times as shown in the illustration.

8. INSTALL FRONT WIPER ARM HEAD CAP

(a) Engage the 3 claws to install the front wiper arm head cap.

HINT:

Use the same procedure for both sides.

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT WINDSHIELD WIPER MOTOR ASSEMBLY

(a) Check the LO operation.

Text in Illustration

*a

Component without harness connected

(Windshield Wipe ...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WIPER ARM HEAD CAP

(a) Using a screwdriver with its tip wrapped in protective tape, disengage

the 3 claws to remove the front wiper arm head cap.

...

Other materials:

Installation

INSTALLATION

CAUTION / NOTICE / HINT

PROCEDURE

1. INSTALL REAR AIRBAG SENSOR LH

(a) Check that the ignition switch is OFF.

(b) Check that the cable is disconnected from the battery negative (-) terminal.

CAUTION:

After disconnecting the cable from the terminal, wait for at least 90 seconds

...

Driver Side Door Entry Lock and Unlock Functions do not Operate

DESCRIPTION

If the entry lock and unlock functions do not operate for the driver door only,

the request code may not be being transmitted from the driver door or the front

door outside handle assembly LH (touch sensor) may be malfunctioning. If the entry

functions for other doors operate prop ...

Brake Switch "A" Signal Compare Failure (P057162)

DESCRIPTION

When the brake pedal is depressed, stop light switch assembly sends a signal

to the ECM. Upon receiving the signal, the ECM cancels the cruise control system.

DTC Code

DTC Detection Condition

Trouble Area

MIL

Note

...

.png)

.png)