Toyota Tacoma (2015-2018) Service Manual: Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

- Always use a new grommet and valve core when installing the tire pressure warning valve and transmitter.

- Check that the washer and nut are not damaged, and replace them if necessary.

- If installing a new tire pressure warning valve and transmitter, write down the ID number before installation.

- Check that there is no oil, water or lubricant around the rim hole, tire pressure warning valve and transmitter, washer and nut. Failing to do so may result in improper installation.

- Use only a specified cap. If an unspecified cap is used, it may seize to the tire pressure warning valve and transmitter.

PROCEDURE

1. INSTALL TIRE PRESSURE WARNING VALVE AND TRANSMITTER

(a) Install a new grommet to the tire pressure warning valve and transmitter.

|

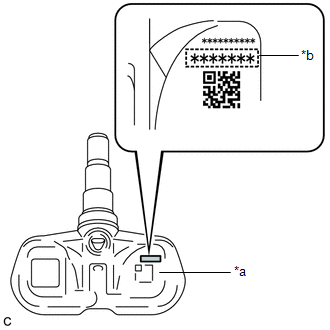

(b) Insert the tire pressure warning valve and transmitter into the valve installation hole. Insert it from the inside of the rim so that the printed surface can be seen. Text in Illustration

NOTICE:

|

|

|

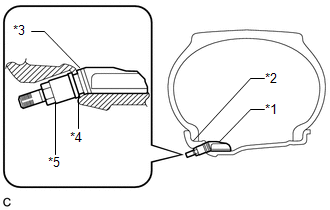

(c) From the outside of the rim, install the washer onto the tire pressure warning valve and transmitter, and tighten the nut. Text in Illustration

Torque: 4.0 N·m {41 kgf·cm, 35 in·lbf} NOTICE:

|

|

|

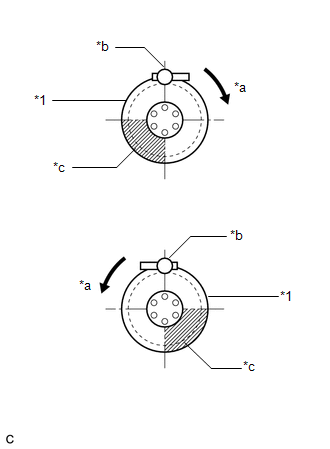

(d) Set the wheel onto the mounting machine and install the lower bead. Position the main body of the tire pressure warning valve and transmitter in the shaded area shown in the illustration. Text in Illustration

NOTICE:

|

|

(e) Install the upper bead.

NOTICE:

Make sure that the tire bead and tool do not interfere with the main body of the tire pressure warning valve and transmitter and that it is not clamped by the bead.

(f) Install a new valve core.

(g) After the tire is inflated, the valve nut may be loose. Retighten the nut to the specified torque.

Torque:

4.0 N·m {41 kgf·cm, 35 in·lbf}

NOTICE:

No further tightening is required once the nut is tightened to the specified torque.

(h) Check for air leaks with soapy water. If there is air leakage, push the valve core 2 or 3 times to remove any dirt attached to the valve core. If air continues to leak, replace the grommet, washer and nut.

(i) Install the cap.

2. INSTALL FRONT WHEEL

Torque:

113 N·m {1152 kgf·cm, 83 ft·lbf}

3. INSTALL REAR WHEEL

Torque:

113 N·m {1152 kgf·cm, 83 ft·lbf}

4. INSPECT TIRES

.gif)

5. REGISTER TRANSMITTER ID

(See page .gif) )

)

6. PERFORM INITIALIZATION

(See page .gif) )

)

7. INSPECT TIRE PRESSURE WARNING SYSTEM

(See page .gif) )

)

Disposal

Disposal

DISPOSAL

CAUTION / NOTICE / HINT

HINT:

The tire pressure warning valve and transmitter is powered by a lithium battery.

When disposing of the tire pressure warning valve and transmitter, remove t ...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEEL

2. REMOVE REAR WHEEL

3. REMOVE TIRE PRESSURE WARNING VALVE AND TRANSMITTER

(a) Remove the cap and valve core to release the air from the tire.

NOTICE:

Ke ...

Other materials:

Operation Check

OPERATION CHECK

1. CHECK POWER DOOR LOCK OPERATION

NOTICE:

The operation check below is based on the non-customized initial condition of

the vehicle.

(a) Check basic functions.

(1) Check that all doors lock when the lock side of the door control switch is

pressed.

(2) Check that all doors ...

Illumination Circuit

DESCRIPTION

Power is supplied to the radio and display receiver assembly and steering pad

switch assembly illumination when the light control switch is in the TAIL or HEAD

position.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

The vehicle is equipped with a Supplemental Restrain ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK BRAKE BOOSTER ASSEMBLY

(a) Airtightness check.

Text in Illustration

*a

Correct

*b

Incorrect

(1) Start the engine and stop it after 1 or 2 minut ...