Toyota Tacoma (2015-2018) Service Manual: Installation

INSTALLATION

PROCEDURE

1. INSTALL HYDRAULIC BRAKE BOOSTER

(a) Install a new brake booster gasket onto the hydraulic brake booster.

(b) Install the hydraulic brake booster with the 4 nuts.

Torque:

14 N·m {145 kgf·cm, 10 ft·lbf}

|

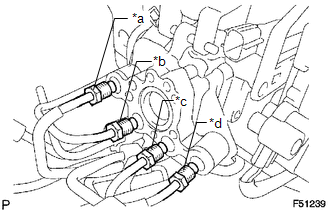

(c) Using a union nut wrench, connect the 4 brake lines to the correct positions of the hydraulic brake booster, as shown in the illustration. Text in Illustration

Torque: without union nut wrench : 15 N·m {155 kgf·cm, 11 ft·lbf} with union nut wrench : 14 N·m {145 kgf·cm, 10 ft·lbf} HINT:

|

|

(d) Connect the 3 connectors.

2. INSTALL MASTER CYLINDER PUSH ROD CLEVIS

.gif)

.gif)

3. INSTALL LOWER NO. 1 INSTRUMENT PANEL AIRBAG ASSEMBLY

(See page .gif)

.gif) )

)

4. INSPECT BRAKE PEDAL HEIGHT

.gif)

5. INSPECT PEDAL FREE PLAY

.gif)

6. INSPECT PEDAL RESERVE DISTANCE

.gif)

7. FILL RESERVOIR WITH BRAKE FLUID

.gif)

8. BLEED BRAKE BOOSTER WITH ACCUMULATOR PUMP ASSEMBLY

.gif)

9. BLEED BRAKE LINE

.gif)

10. BLEED MASTER CYLINDER SOLENOID

.gif)

11. INSPECT FLUID LEVEL IN RESERVOIR

.gif)

12. INSPECT FOR BRAKE FLUID LEAK

13. INSPECT BRAKE MASTER CYLINDER OPERATION

.gif)

Disposal

Disposal

DISPOSAL

PROCEDURE

1. DISPOSE OF BRAKE BOOSTER ACCUMULATOR ASSEMBLY

(a) Place the brake booster accumulator in a vise and cover it with a cloth.

(b) Slowly cut a hole on the brake booster accumu ...

Rear Brake

Rear Brake

...

Other materials:

GPS Mark is not Displayed

PROCEDURE

1.

CHECK CABIN

(a) Check the cabin for any object that might interrupt radio reception or additional

devices which use radio waves on the instrument panel. If such an object exists,

remove it and check if the GPS mark reappears.

HINT:

The GPS uses ex ...

Clutch Release Cylinder(for Rc62f)

Components

COMPONENTS

ILLUSTRATION

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE CLUTCH RELEASE CYLINDER KIT

(a) Remove the boot from the cylinder body.

(b) Remove the push rod from the boot.

(c) Using compressed air, remove the piston together with the spring

from the cy ...

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEEL

2. REMOVE REAR WHEEL

3. REMOVE TIRE PRESSURE WARNING VALVE AND TRANSMITTER

(a) Remove the cap and valve core to release the air from the tire.

NOTICE:

Keep the removed cap and valve core.

(b) After ensuring that a sufficient amount of air has been rele ...