Toyota Tacoma (2015-2018) Service Manual: Installation

INSTALLATION

PROCEDURE

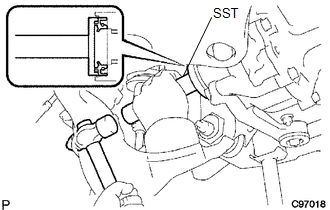

1. INSTALL DIFFERENTIAL SIDE GEAR SHAFT OIL SEAL

(a) Using SST and a hammer, install a new oil seal.

SST: 09554-30011

(b) Coat the oil seal lip with MP grease.

2. INSTALL FRONT DRIVE SHAFT ASSEMBLY LH

Click here .gif)

3. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH

HINT:

Use the same procedure as for the LH side.

4. INSTALL FRONT SUSPENSION LOWER ARM LH

Click here .gif)

5. INSTALL FRONT SUSPENSION LOWER ARM RH

HINT:

Use the same procedure as for the LH side.

6. INSTALL TIE ROD END SUB-ASSEMBLY LH

Click here .gif)

7. INSTALL TIE ROD END SUB-ASSEMBLY RH

HINT:

Use the same procedure as for the LH side.

8. INSTALL FRONT SPEED SENSOR LH

Click here .gif)

9. INSTALL FRONT SPEED SENSOR RH

HINT:

Use the same procedure as for the LH side.

10. INSTALL FRONT STABILIZER LINK ASSEMBLY LH

Click here .gif)

11. INSTALL FRONT STABILIZER LINK ASSEMBLY RH

HINT:

Use the same procedure as for the LH side.

12. INSTALL FRONT AXLE SHAFT LH NUT

Click here .gif)

13. INSTALL FRONT AXLE SHAFT RH NUT

HINT:

Use the same procedure as for the LH side.

14. ADD DIFFERENTIAL OIL

Click here .gif)

15. INSPECT DIFFERENTIAL OIL

Click here .gif)

16. INSTALL NO. 1 ENGINE UNDER COVER SUB-ASSEMBLY

Torque:

30 N·m {306 kgf·cm, 22 ft·lbf}

17. INSTALL NO. 2 ENGINE UNDER COVER SUB-ASSEMBLY (w/ Engine Under Cover No, 2)

Torque:

30 N·m {306 kgf·cm, 22 ft·lbf}

18. INSTALL FRONT WHEELS

Torque:

113 N·m {1152 kgf·cm, 83 ft·lbf}

19. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

Click here .gif)

20. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Torque:

5.4 N·m {55 kgf·cm, 48 in·lbf}

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

Click here .gif)

21. CHECK VSC SENSOR SIGNAL (for Hydraulic Brake Booster)

Click here .gif)

22. CHECK VSC SENSOR SIGNAL (for Vacuum Brake Booster)

Click here .gif)

Removal

Removal

REMOVAL

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting

the cable from the negative (-) battery terminal. Therefore, make ...

Other materials:

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE OIL PUMP RELIEF VALVE

(a) Using a 27 mm socket wrench, remove the oil pump relief valve plug.

(b) Remove the oil pump relief valve spring and oil pump relief valve.

(c) Remove the spring and relief valve.

2. R ...

Slip Indicator Light does not Come ON

DESCRIPTION

Refer to Slip Indicator Light Remains ON (See page

).

WIRING DIAGRAM

Refer to Slip Indicator Light Remains ON (See page

).

CAUTION / NOTICE / HINT

NOTICE:

When replacing the skid control ECU (brake actuator assembly), perform zero point

calibration and store system informatio ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL NO. 1 STEREO JACK ADAPTER ASSEMBLY

(a) Engage the 2 claws to install the No. 1 stereo jack adapter assembly.

2. INSTALL INSTRUMENT PANEL LOWER CENTER FINISH PANEL

(See page )

3. INSTALL NO. 2 INSTRUMENT PANEL GARNISH SUB-ASSEMBLY

(See page )

4. INSTALL F ...