Toyota Tacoma (2015-2018) Service Manual: Inspection

INSPECTION

PROCEDURE

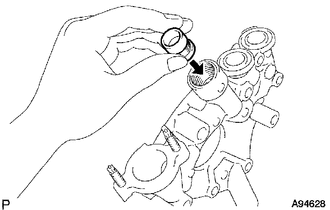

1. INSPECT OIL PUMP RELIEF VALVE

|

(a) Coat the oil pump relief valve with engine oil and check that it falls smoothly into the valve hole by its own weight. If the valve does not fall smoothly, replace the timing chain cover assembly. |

|

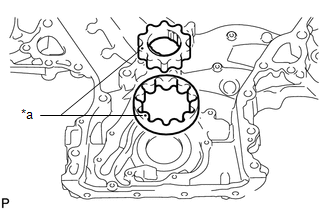

2. INSPECT OIL PUMP ROTOR SET

|

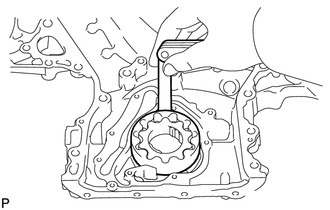

(a) Place the drive and driven rotors into the timing chain cover with the marks facing upward. Text in Illustration

|

|

(b) Check the rotor tip clearance.

|

(1) Using a feeler gauge, measure the clearance between the drive and driven rotor tips. Standard tip clearance: 0.06 to 0.16 mm (0.00236 to 0.00630 in.) Maximum tip clearance: 0.16 mm (0.00630 in.) If the clearance is more than the maximum, replace the drive and driven rotors as a set. |

|

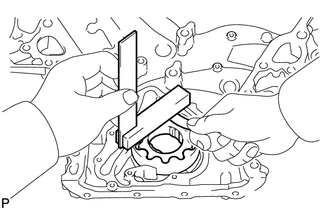

(c) Check the rotor side clearance.

|

(1) Using a feeler gauge and steel square, measure the clearance between the rotors and precision straightedge. Standard side clearance: 0.030 to 0.075 mm (0.00118 to 0.00295 in.) Maximum side clearance: 0.075 mm (0.00295 in.) If the clearance is more than the maximum, replace the drive and driven rotors as a set. If necessary, replace the timing chain cover assembly. |

|

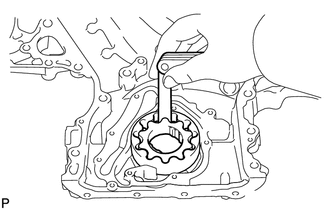

(d) Check the rotor body clearance.

|

(1) Using a feeler gauge, measure the clearance between the driven rotor and body. Standard body clearance: 0.250 to 0.325 mm (0.00984 to 0.0128 in.) Maximum body clearance: 0.325 mm (0.0128 in.) If the clearance is more than the maximum, replace the drive and driven rotors as a set. If necessary, replace the timing chain cover assembly. |

|

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE OIL PUMP RELIEF VALVE

(a) Using a 27 mm socket wrench, remove the oil pump relief valve plug.

(b) Remove the oil pump relief valve spring and oil pump re ...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE ENGINE ASSEMBLY

(See page )

2. REMOVE IGNITION COIL ASSEMBLY

3. REMOVE ENGINE OIL LEVEL DIPSTICK GUIDE

4. REMOVE CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY ...

Other materials:

Oil Level Sensor

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT ENGINE OIL LEVEL SENSOR

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection

Condi ...

Components

COMPONENTS

ILLUSTRATION

*1

FRONT ARMREST BASE UPPER PANEL SUB-ASSEMBLY

*2

FRONT DOOR GLASS INNER WEATHERSTRIP

*3

FRONT DOOR INSIDE HANDLE BEZEL PLUG

*4

FRONT DOOR INSIDE HANDLE SUB-ASSEMBLY

...

Transmission Control Switch Circuit

DESCRIPTION

After moving the shift lever to S, it is possible to switch the shift range between

"1" (S1 range) and "6" (S6 range) using the transmission control switch.

Moving the shift lever to "+" once raises the shift range by one, and moving

the shift lever to ...