Toyota Tacoma (2015-2018) Service Manual: Inspection

INSPECTION

PROCEDURE

1. INSPECT NO. 1 ULTRASONIC SENSOR

|

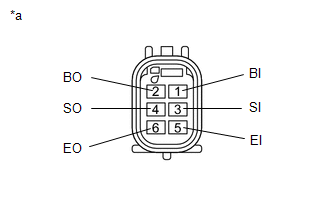

(a) Measure the resistance according to the value(s) in the table below. Text in Illustration

Standard Resistance:

If the result is not as specified, replace the No. 1 ultrasonic sensor. |

|

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE REAR BUMPER ASSEMBLY (w/ Towing Package)

(See page )

2. REMOVE REAR BUMPER ASSEMBLY (w/o Towing Package)

(See page )

3. REMOVE CONNECTOR COVER (w/ Towing Package) ...

Other materials:

Definition Of Terms

DEFINITION OF TERMS

Term

Definition

Monitor description

Description of what the ECM monitors and how it detects malfunctions

(monitoring purpose and details).

Related DTCs

Group of diagnostic trouble codes that are ou ...

Rear Airbag Sensor LH Circuit Malfunction (B1635/24)

DESCRIPTION

The airbag sensor LH consists of parts such as the safing sensor, the diagnostic

circuit and the lateral deceleration sensor.

When the airbag sensor assembly receives signals from the lateral deceleration

sensor, it determines whether or not the SRS should be activated.

DTC B1635/ ...

Operation Check

OPERATION CHECK

1. CHECK NAVIGATION SYSTEM NORMAL CONDITION

(a) If the symptom is applicable to any of the following, it is intended behavior,

and not a malfunction.

Symptom

Answer

A longer route than expected is chosen.

Depending on the road co ...