Toyota Tacoma (2015-2018) Service Manual: Transfer L4 Position Switch Circuit (C1268)

DESCRIPTION

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

|---|---|---|---|

|

C1268 |

Transfer L4 Position Switch Circuit |

Either of the following is detected:

|

|

HINT:

DTC will be output when conditions for either of the patterns in the table above are met.

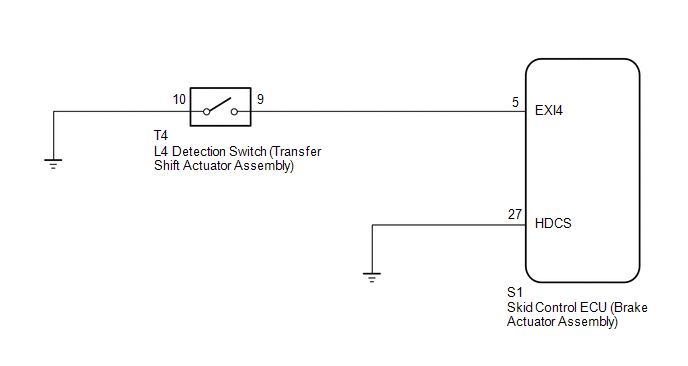

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

When replacing the skid control ECU (brake actuator assembly), perform zero point

calibration and store system information (See page

.gif)

.gif) ).

).

PROCEDURE

|

1. |

INSPECT L4 DETECTION SWITCH (TRANSFER SHIFT ACTUATOR ASSEMBLY) |

(a) Inspect the transfer shift actuator assembly (See page

.gif) ).

).

OK:

The transfer shift actuator assembly is normal.

| NG | .gif) |

REPLACE TRANSFER SHIFT ACTUATOR ASSEMBLY |

|

|

2. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - L4 DETECTION SWITCH) |

(a) Disconnect the S1 skid control ECU (brake actuator assembly) connector.

(b) Disconnect the T4 L4 detection switch (Transfer shift actuator assembly) connector.

(c) Measure the resistance according to the value(s) in the table below

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

S1-5 (EXI4) - T4-9 |

Always |

Below 1 Ω |

|

S1-5 (EXI4) - Body ground |

Always |

10 kΩ or higher |

|

T4-10 - Body ground |

Always |

Below 1 Ω |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (L4 DETECTION SWITCH CIRCUIT) |

|

|

3. |

CHECK HARNESS AND CONNECTOR (HDCS TERMINAL) |

|

(a) Disconnect the skid control ECU (brake actuator assembly) connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

S1-27 (HDCS) - Body ground |

Always |

Below 1 Ω |

|

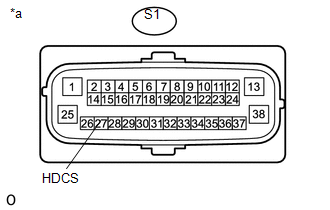

*a |

Front view of wire harness connector (to Skid Control ECU (Brake Actuator Assembly)) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

RECONFIRM DTC |

(a) Clear the DTC (See page .gif)

.gif) ).

).

(b) Check if the same DTC is recorded (See page

.gif)

.gif) ).

).

|

Result |

Proceed to |

|---|---|

|

DTC is output |

A |

|

DTC is not output |

B |

| A | .gif) |

REPLACE BRAKE ACTUATOR ASSEMBLY |

| B | .gif) |

USE SIMULATION METHOD TO CHECK |

Vehicle Control History

Vehicle Control History

VEHICLE CONTROL HISTORY

VEHICLE CONTROL HISTORY

(a) A part of the control history can be confirmed using the vehicle control

history.

Click here ...

Steering Angle Sensor Zero Point Malfunction (C1290)

Steering Angle Sensor Zero Point Malfunction (C1290)

DESCRIPTION

The skid control ECU (brake actuator assembly) acquires steering angle sensor

zero point every time the ignition switch is turned ON and the vehicle is driven

at 35 km/h (22 mph) or m ...

Other materials:

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) When troubleshooting OBD II (On-Board Diagnostics) vehicles, an OBD II scan

tool (complying with SAE J1978) must be connected to the DLC3 (Data Link Connector

3) of the vehicle. Various data in the vehicle ECM (Engine Control Module) can be

then read.

(b) ...

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

The ECM of this system is connected to the CAN communication system.

Therefore, before starting troubleshooting, make sure to check that there

is no trouble in the CAN and multiplex communication system.

*: Use the Techstream.

PROCEDURE

...

Freeze Frame Data

FREEZE FRAME DATA

1. FREEZE FRAME DATA

(a) Whenever a DTC is detected, the blind spot monitor sensor stores the current

vehicle (sensor) state as Freeze Frame Data.

2. CHECK FREEZE FRAME DATA

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the blind spot ...

.gif)