Toyota Tacoma (2015-2018) Service Manual: Clutch Start Cancel Switch

Inspection

INSPECTION

PROCEDURE

1. INSPECT CLUTCH START CANCEL SWITCH ASSEMBLY

|

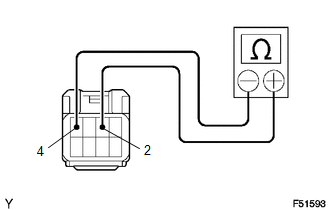

(a) Using an ohmmeter, check that there is resistance between terminals 2 and 4. Standard: 10 kΩ or higher If the result is not as specified, replace the clutch start cancel switch. |

|

|

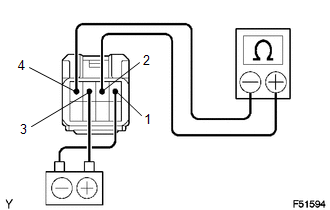

(b) Connect the positive (+) lead from the battery to terminal 3 and connect negative (-) lead to terminal 1. |

|

(c) Using an ohmmeter, check that there is resistance between terminals 2 and 4.

Standard:

10 kΩ or higher

If the result is not as specified, replace the clutch start cancel switch.

|

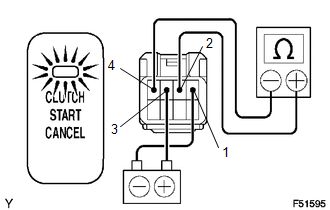

(d) Check that the indicator light comes on and there is resistance between terminals 2 and 4 when the switch is pressed. Standard: Below 1 Ω If the result is not as specified, replace the clutch start cancel switch. |

|

|

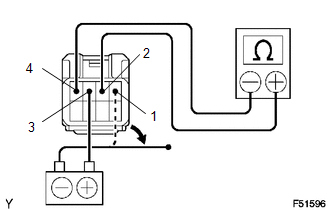

(e) Using an ohmmeter, check that there is resistance between terminals 2 and 4 when the battery lead is disconnected. Standard: 10 kΩ or higher If the result is not as specified, replace the clutch start cancel switch. |

|

Clutch Release Cylinder(for Rc62f)

Clutch Release Cylinder(for Rc62f)

Components

COMPONENTS

ILLUSTRATION

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE CLUTCH RELEASE CYLINDER KIT

(a) Remove the boot from the cylinder body.

(b) Remove the push rod from the bo ...

Clutch System

Clutch System

...

Other materials:

SRS Warning Light Remains ON

DESCRIPTION

The SRS warning light is located on the combination meter assembly.

When the SRS condition is normal, the SRS warning light illuminates for approximately

6 seconds after the ignition switch is turned from off to ON, and then turns off

automatically.

If there is a malfunction in th ...

Luggage compartment features

Behind the rear seat (Double

Cab models only)

1.Cargo net hooks (vehicles with sub woofer)

2.Grocery bag hooks

3.Flashlight holder

4.Storage boxes

Deck

1. Auxiliary boxes

2. Tie-down cleats

3. Deck hooks

Auxiliary boxes

Left side

1. Turn the knob counterclockwise.

2. Open the ...

Steering Angle Sensor (C1A47)

DESCRIPTION

The forward recognition camera receives steering angle information from the spiral

cable with sensor sub-assembly. If the forward recognition camera detects a spiral

cable with sensor sub-assembly malfunction, DTC C1A47 is stored.

DTC No.

Detection Item

...