Toyota Tacoma (2015-2018) Service Manual: System Diagram

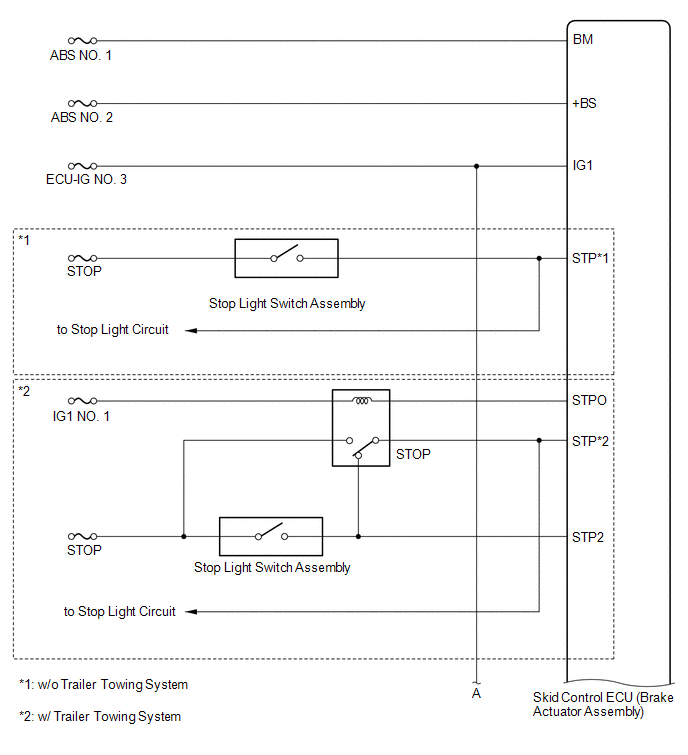

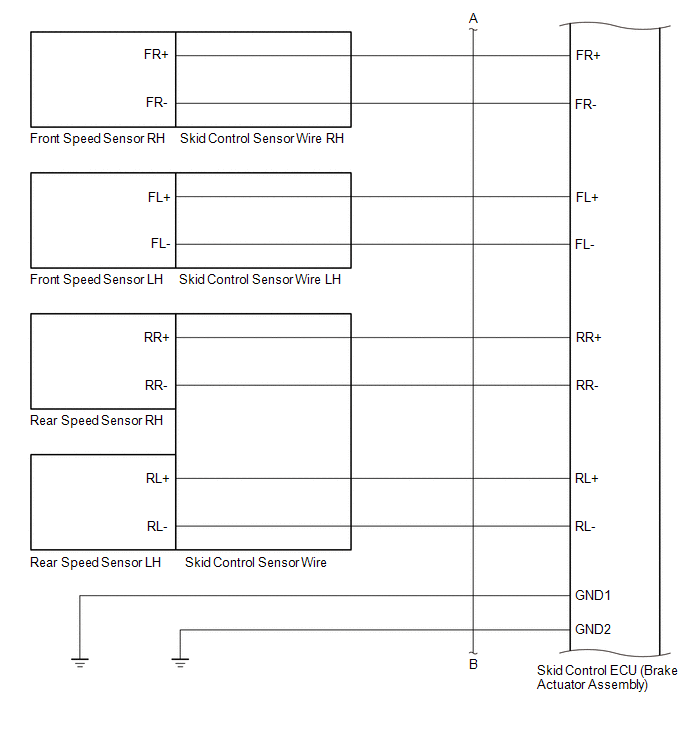

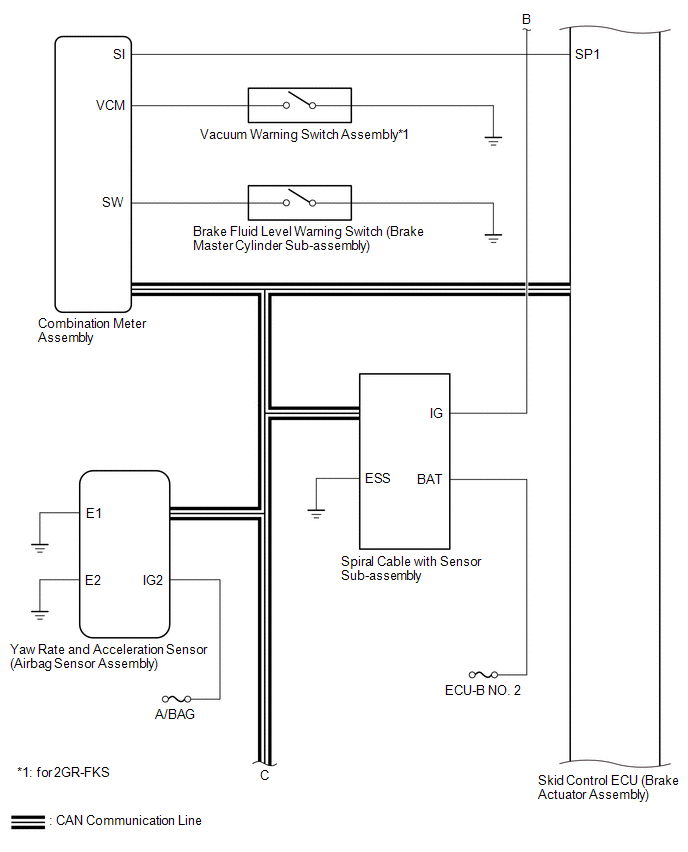

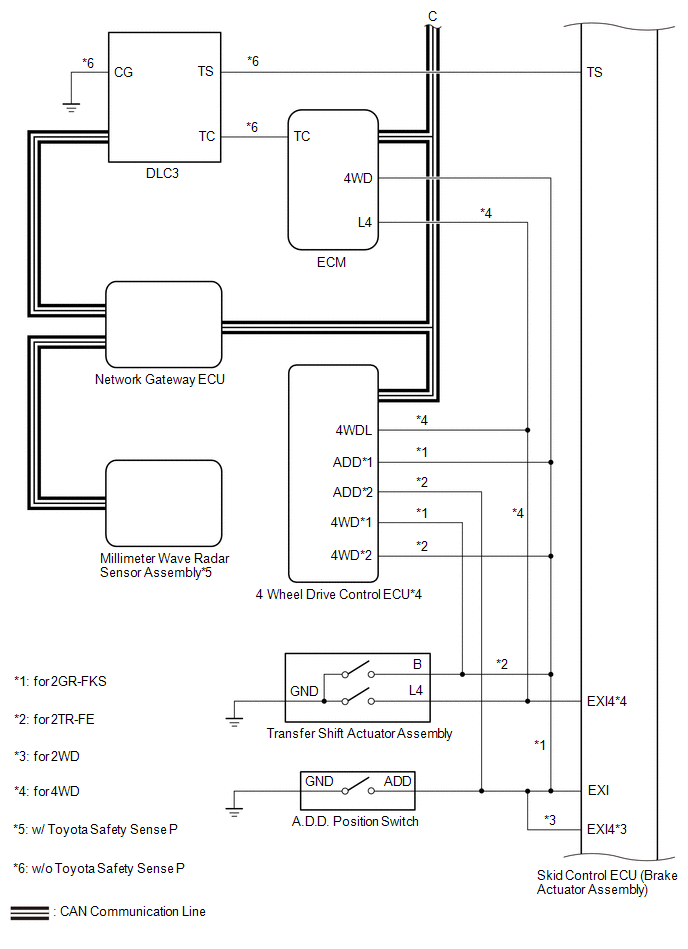

SYSTEM DIAGRAM

|

Transmitting ECU (Transmitter) |

Receiving ECU |

Signal |

Communication Method |

|---|---|---|---|

|

Skid control ECU (Brake actuator assembly) |

Steering angle sensor (Spiral cable with sensor sub-assembly) |

Steering angle sensor request signal |

CAN communication system |

|

Steering angle sensor (Spiral cable with sensor sub-assembly) |

Skid control ECU (Brake actuator assembly) |

Steering angle sensor signal |

CAN communication system |

|

Skid control ECU (Brake actuator assembly) |

Yaw rate and acceleration sensor (Airbag sensor assembly) |

Yaw rate and acceleration request signal |

CAN communication system |

|

Yaw rate and acceleration sensor (Airbag sensor assembly) |

Skid control ECU (Brake actuator assembly) |

Yaw rate and acceleration signal |

CAN communication system |

|

Skid control ECU (Brake actuator assembly) |

ECM |

|

CAN communication system |

|

ECM |

Skid control ECU (Brake actuator assembly) |

|

CAN communication system |

|

Skid control ECU (Brake actuator assembly) |

Combination meter assembly |

|

CAN communication system |

|

Wheel speed signal |

Serial communication |

||

|

4 wheel drive control ECU*3 |

Skid control ECU (Brake actuator assembly) |

|

CAN communication system |

- *1: for 4WD

- *2: w/ Rear Differential Lock

- *3: for 4WD or with Rear Differential Lock

- *4: w/o Toyota Safety Sense P

System Description

System Description

SYSTEM DESCRIPTION

1. FUNCTION DESCRIPTION

(a) ABS (Anti-lock Brake System)

(1) The ABS helps prevent the wheels from locking when the brakes are applied

firmly or when braking on a slippery surf ...

Check For Intermittent Problems

Check For Intermittent Problems

CHECK FOR INTERMITTENT PROBLEMS

1. CHECK FOR INTERMITTENT PROBLEMS

HINT:

A momentary interruption (open circuit) in the connectors and/or wire harnesses

between the sensors and ECUs can be detect ...

Other materials:

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for both the RH and LH sides.

The procedure described below is for the LH side.

PROCEDURE

1. INSTALL SIDE AIRBAG SENSOR ASSEMBLY

(a) Check that the ignition switch is OFF.

(b) Check that the cable is disconnec ...

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

Use the following procedure to troubleshoot the manual transaxle system.

*: Use the Techstream.

PROCEDURE

1.

VEHICLE BROUGHT TO WORKSHOP

NEXT

...

Mute Signal Circuit between Radio Receiver and Stereo Component Amplifier

DESCRIPTION

This circuit sends a signal to the stereo component amplifier assembly to mute

noise. Because of that, the noise produced by changing the sound source ceases.

If there is an open in the circuit, noise can be heard from the speakers when

changing the sound source.

If there is a sho ...