Toyota Tacoma (2015-2018) Service Manual: Removal

REMOVAL

CAUTION / NOTICE / HINT

.png) Text in Illustration

Text in Illustration

|

*a |

Object Exceeding Weight Limit of Transmission Jack |

- Be sure to perform this procedure with several people as the rear differential carrier assembly is very heavy.

- Be sure to follow the procedure described in the repair manual, or the transmission jack may suddenly drop or a part may fall.

HINT:

The following procedures are for BD22 (w/o Differential Lock).

PROCEDURE

1. REMOVE REAR WHEELS

2. REMOVE REAR PROPELLER SHAFT ASSEMBLY (for 2WD)

(See page .gif) )

)

3. REMOVE REAR PROPELLER SHAFT ASSEMBLY (for 4WD)

(See page .gif) )

)

4. DRAIN DIFFERENTIAL OIL

(See page .gif) )

)

5. REMOVE REAR AXLE SHAFT WITH BACKING PLATE LH

(See page .gif)

.gif) )

)

6. REMOVE REAR AXLE SHAFT WITH BACKING PLATE RH

HINT:

Use the same procedure described for the LH side.

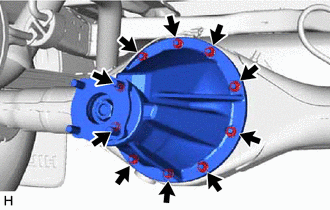

7. REMOVE REAR DIFFERENTIAL CARRIER ASSEMBLY

|

(a) Remove the 10 nuts, 10 washers and rear differential carrier assembly. CAUTION: The rear differential carrier assembly is a heavy component. Make sure that it is supported securely. NOTICE:

|

|

8. REMOVE REAR DIFFERENTIAL CARRIER GASKET

Components

Components

COMPONENTS

ILLUSTRATION

HINT:

The following specifications are for BD22A (w/o Differential Lock). BD22A differentials

are equipped with M10 rear differential carrier to rear axel housing fastener ...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT DIFFERENTIAL PINION AND SIDE GEAR

(a) Check that there is no damage to the pinion gear or side gear.

If the pinion gear and/or side gear is damaged, replace the dif ...

Other materials:

Driving the vehicle

The following procedures should be observed to ensure safe driving.

■ Starting the engine

■ Driving

Automatic transmission

With the brake pedal depressed,

shift the shift lever to D.

Release the parking brake.

Gradually release the brake pedal

and gently depress the acceler ...

Pressure Control Solenoid "G" Performance (Shift Solenoid Valve SL4) (P2808)

SYSTEM DESCRIPTION

The ECM uses the vehicle speed signal and signals from the transmission revolution

sensors (NT, SP2) to detect the actual gear (1st, 2nd, 3rd, 4th, 5th or 6th gear).

The ECM compares the actual gear with the shift schedule in the ECM memory to

detect mechanical problems of t ...

Terminals Of Ecm

TERMINALS OF ECM

1. ECM

HINT:

The standard voltage between each pair of ECM terminals is shown in the table

below. In the table, first follow the information under "Condition". Look under

"Terminal No. (Symbol)" for the terminals to be inspected. The standard voltage

b ...