Toyota Tacoma (2015-2018) Service Manual: Removal

REMOVAL

PROCEDURE

1. DRAIN AUTOMATIC TRANSMISSION FLUID

|

(a) Remove the drain plug and gasket from the automatic transmission assembly and drain the ATF. |

|

(b) Install a new gasket and the drain plug to the automatic transmission assembly.

Torque:

20 N·m {204 kgf·cm, 15 ft·lbf}

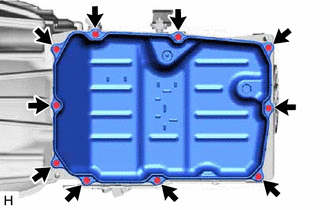

2. REMOVE AUTOMATIC TRANSMISSION OIL PAN SUB-ASSEMBLY

|

(a) Remove the 10 bolts, automatic transmission oil pan sub-assembly and automatic transmission oil pan gasket from the automatic transmission case sub-assembly. NOTICE: Some fluid will remain in the automatic transmission oil pan sub-assembly. Remove all of the bolts, and carefully remove the automatic transmission oil pan sub-assembly. |

|

(b) Remove the 4 transmission oil cleaner magnets from the automatic transmission oil pan sub-assembly.

(c) Examine the particles in the automatic transmission oil pan sub-assembly.

(1) Collect any steel chips with the removed transmission oil cleaner magnets. Carefully inspect the foreign matter and particles in the automatic transmission oil pan sub-assembly and on the transmission oil cleaner magnets to anticipate the type of wear you will find in the automatic transmission assembly.

Steel (magnetic): bearing, gear and clutch plate wear

Brass (non-magnetic): bush wear

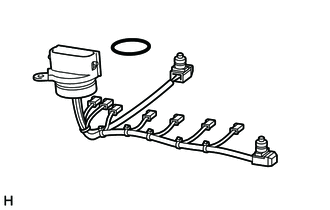

3. DISCONNECT TRANSMISSION WIRE

|

(a) Remove the 2 bolts and the 2 temperature sensor clamps, and disconnect the 2 temperature sensors. Text in Illustration

|

|

(b) Disconnect the 7 solenoid valve connectors and transmission wire from the transmission valve body assembly.

4. REMOVE TRANSMISSION INSULATOR RH (for 2GR-FKS)

|

(a) Remove the bolt and wire harness clamp bracket from the transmission insulator RH. |

|

(b) Remove the 2 bolts and transmission insulator RH from the automatic transmission assembly.

5. REMOVE TRANSMISSION INSULATOR RH (for 2TR-FE)

|

(a) Remove the 3 bolts and transmission insulator RH from the automatic transmission assembly. |

|

6. REMOVE TRANSMISSION WIRE

|

(a) Disconnect the transmission wire connector. HINT: Detach the claw, press down the lever, and disconnect the transmission wire connector. |

|

(b) Remove the bolt and pull out the transmission wire from the automatic transmission case sub-assembly.

|

(c) Remove the O-ring from the connector of transmission wire. |

|

|

(d) Remove the 2 O-rings from the 2 temperature sensors. |

|

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT TRANSMISSION WIRE

(a) Measure the resistance according to the value(s) in the table below.

Text in Illustration

*a

...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL TRANSMISSION WIRE

(a) Coat 2 new O-rings with ATF, and install them to the 2 temperature sensors.

(b) Coat a new O-ring with ATF, and install it to the transmissi ...

Other materials:

Front Passenger Side Power Window Auto Up / Down Function does not Operate with

Front Passenger Side Power Window Switch

DESCRIPTION

If the manual up/down function can be performed but the auto up/down function

cannot, the fail-safe mode may be functioning.

If the power window initialization (See page

) has not been performed, the auto up/down function will not operate.

WIRING DIAGRAM

CAUTION / NOTICE / HIN ...

Stop Light Relay Circuit (C1A4B)

DESCRIPTION

The skid control ECU (master cylinder solenoid)*1 or skid control ECU (brake

actuator assembly)*2 sends a stop light operation request signal to the stop light

relay (stop light switch assembly). If the skid control ECU (master cylinder solenoid)*1

or skid control ECU (brake actua ...

Removal

REMOVAL

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting

the cable from the negative (-) battery terminal. Therefore, make sure to read the

disconnecting the cable from the negative (-) battery terminal notices before pr ...

.png)