Toyota Tacoma (2015-2018) Service Manual: Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL NO. 3 REAR BODY NAME PLATE (for 2GR-FKS)

.gif)

.gif)

2. INSTALL NO. 2 REAR BODY NAME PLATE (for 4WD)

.gif)

.gif)

3. INSTALL SIDE GATE SUPPORT FEMALE HINGE RH

|

(a) Engage the claw to install the side gate support female hinge RH. |

|

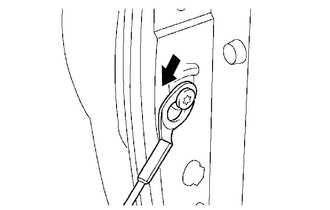

4. INSTALL TAIL GATE HINGE ASSEMBLY RH

|

(a) Using a T40 "TORX" socket wrench, install the tail gate hinge assembly RH with the bolt and 2 screws. Torque: Bolt : 27 N·m {275 kgf·cm, 20 ft·lbf} Screw : 27 N·m {275 kgf·cm, 20 ft·lbf} |

|

5. INSTALL TAIL GATE HINGE ASSEMBLY LH

|

(a) Using a T40 "TORX" socket wrench, install the tail gate hinge assembly LH with the bolt and 2 screws. Torque: Bolt : 27 N·m {275 kgf·cm, 20 ft·lbf} Screw : 27 N·m {275 kgf·cm, 20 ft·lbf} |

|

6. INSTALL TAIL GATE STAY ASSEMBLY

|

(a) Using a T40 "TORX" socket wrench, install the tail gate stay assembly with the tail gate stay shaft and washer. Torque: 26 N·m {260 kgf·cm, 19 ft·lbf} HINT: Use the same procedure for the LH side and RH side. |

|

7. INSTALL TAIL GATE STAY STOPPER

|

(a) Using a T40 "TORX" socket wrench, install the tail gate stopper with the tail gate stay shaft. Torque: 26 N·m {260 kgf·cm, 19 ft·lbf} HINT: Use the same procedure for the LH side and RH side. |

|

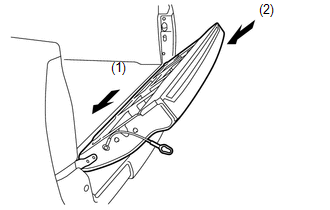

8. INSTALL TAIL GATE

|

(a) Install the tail gate onto the vehicle by engaging the hinge on the left side first and then the hinge on the right side. NOTICE: Be careful not to drop the tail gate. |

|

|

(b) Engage the tail gate stay to the tail gate stay stopper as shown in the illustration. HINT: Use the same procedure for the LH side and RH side. |

|

|

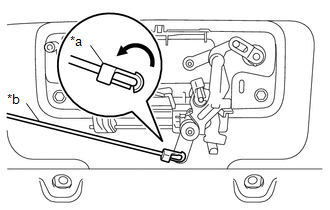

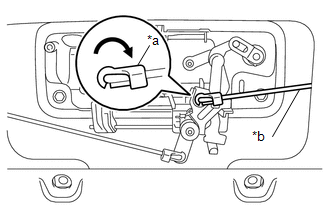

(c) Engage the 2 guides and 2 claws to connect the wire harness from the tail gate. |

|

(d) Engage the clamp.

Text in Illustration|

*a |

Guide |

|

*b |

Clamp |

|

(e) Engage the clamp. |

|

9. INSTALL TAIL GATE LOCK STRIKER

|

(a) Using a T40 "TORX" socket wrench, install the tail gate lock striker with the 2 bolts. Torque: 29 N·m {296 kgf·cm, 21 ft·lbf} HINT: Use the same procedure for the LH side and RH side. |

|

10. INSTALL TAIL GATE HANDLE ASSEMBLY

|

(a) Engage the guide to install the tail gate handle assembly. |

|

(b) Install the 2 bolts.

Torque:

5.5 N·m {56 kgf·cm, 49 in·lbf}

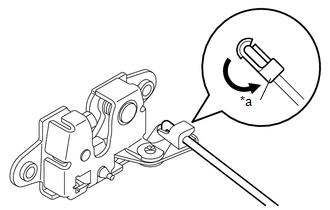

11. INSTALL TAIL GATE LOCK CONTROL LINK

|

(a) Rotate the snap as shown in the illustration to engage the snap to install the tail gate lock control link to tail gate lock assembly LH. Text in Illustration

HINT: Use the same procedure for the LH side and RH side. |

|

12. INSTALL TAIL GATE LOCK ASSEMBLY LH

|

(a) Using a T40 "TORX" socket wrench, install the tail gate lock assembly LH with the 2 bolts. Torque: 29 N·m {296 kgf·cm, 21 ft·lbf} |

|

(b) Engage the clamp.

|

(c) Rotate the snap as shown in the illustration to engage the snap to install the tail gate lock control link to tail gate handle assembly. Text in Illustration

|

|

13. INSTALL TAIL GATE LOCK ASSEMBLY RH

|

(a) Using a T40 "TORX" socket wrench, install the tail gate lock assembly RH with the 2 bolts. Torque: 29 N·m {296 kgf·cm, 21 ft·lbf} |

|

(b) Engage the clamp.

|

(c) Rotate the snap as shown in the illustration to engage the snap to install the tail gate lock control link to tail gate handle assembly. Text in Illustration

|

|

14. INSTALL REAR TELEVISION CAMERA ASSEMBLY

.gif)

15. INSTALL TAIL GATE SERVICE HOLE COVER

|

(a) Using a T30 "TORX" socket wrench, install the tail gate service hole cover with the 8 screws. |

|

16. INSTALL TAIL GATE PROTECTOR

(See page .gif) )

)

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE TAIL GATE PROTECTOR

(See page )

2. REMOVE TAIL GATE SERVICE HOLE COVER

(a) Using a T30 "TORX" socket wrench, remove the 8 screws and tail gat ...

Tonneau Cover Assembly

Tonneau Cover Assembly

Removal

REMOVAL

PROCEDURE

1. REMOVE TOP COVER SUB-ASSEMBLY

(a) Open the cover.

(b) Remove the bolt and top cover sub-assembly.

2. REMOVE RE ...

Other materials:

Transponder Key Amplifier

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL TRANSPONDER KEY COIL

(a) Engage the 2 claws to install the transponder key coil.

(b) Connect the connector.

2. INSTALL UPPER STEERING COLUMN COVER

(S ...

Fail-safe Chart

FAIL-SAFE CHART

HINT:

If any of the following auto cancel conditions are detected while the dynamic

radar cruise control system is controlling vehicle speed, the system clears the

stored vehicle speed and cancels control of vehicle speed by the dynamic radar cruise

control system.

Automatic ...

Front Radar Sensor Region Code Mismatch (C1A0A)

DESCRIPTION

When the destination information in the millimeter wave radar sensor assembly

and forward recognition camera do not match, DTC C1A0A is stored.

DTC No.

Detection Item

DTC Detection Condition

Trouble Area

MIL

C1A0 ...

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)