Toyota Tacoma (2015-2018) Service Manual: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT RADIATOR CAP SUB-ASSEMBLY

CAUTION:

Do not remove the radiator cap sub-assembly while the engine and radiator assembly are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

(a) Measure the valve opening pressure.

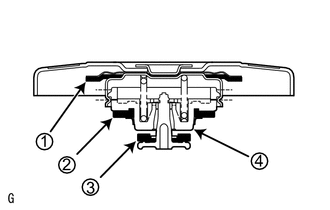

(1) If there are water stains or foreign matter on rubber packing 1, 2 or 3, clean it by using water and finger scouring.

(2) Check that rubber packing 1, 2 and 3 are not deformed, cracked or swollen.

(3) Check that rubber packing 3 and 4 are not stuck together.

(4) Apply engine coolant to rubber packing 2 and 3.

|

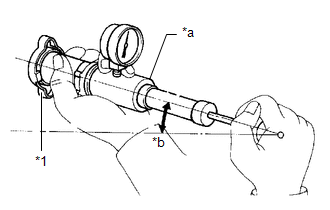

(5) When using the radiator cap tester, tilt it 30° or more. Text in Illustration

|

|

(6) Pump the radiator cap tester several times and check the maximum pressure.*1

Pumping speed:

1 pump per second

HINT:

*1: Even if the radiator cap sub-assembly cannot maintain the maximum pressure, it is not necessarily defective.

Standard Judgment Criterion:

|

Item |

Specified Condition |

|---|---|

|

Standard value (for brand-new cap) |

93 to 123 kPa (1.0 to 1.3 kgf/cm2, 14 to 18 psi) |

|

Minimum standard value (for used cap) |

79 kPa (0.8 kgf/cm2, 11 psi) |

If the maximum pressure is less than the minimum standard value, replace the radiator cap sub-assembly.

2. INSPECT FINS FOR BLOCKAGE

|

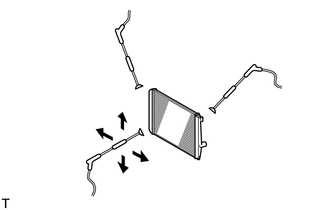

(a) If the fins are clogged, wash them with water or a steam cleaner and dry them with compressed air. NOTICE:

|

|

(b) Dry the fins with compressed air.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE RADIATOR DRAIN COCK PLUG

(a) Remove the radiator drain cock plug from the radiator assembly.

(b) Remove the O-ring from the radiator drain cock plug.

2. REMOVE RAD ...

Other materials:

Inspection

INSPECTION

PROCEDURE

1. INSPECT TIRES

(a) Check the tires for wear and proper inflation pressure.

Standard Cold Tire Inflation Pressure:

Tire Size

Front Wheel

kPa (kgf/cm2, psi)

Rear Wheel

kPa (kgf/cm2, psi)

Spare Wheel

kPa (kgf/cm2, psi)

...

AUTO LSD Indicator Light does not Come ON

DESCRIPTION

The AUTO LSD does not operate even if the VSC OFF switch is pressed under the

following conditions:

The brake system is faulty.

The temperature inside the hydraulic brake booster increases and the

AUTO LSD operation is suspended.

The rear differential is locked.

...

Tachometer Malfunction

DESCRIPTION

In this circuit, the meter CPU receives engine speed signals from the ECM using

the CAN communication system (CAN V1 Bus). The meter CPU displays the engine speed

calculated based on the data received from the ECM.

WIRING DIAGRAM

PROCEDURE

1.

CHECK CAN CO ...