Toyota Tacoma (2015-2018) Service Manual: Installation

INSTALLATION

PROCEDURE

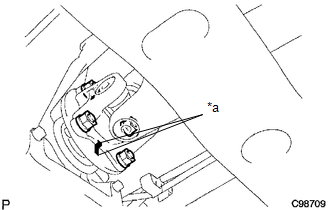

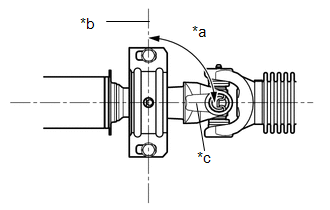

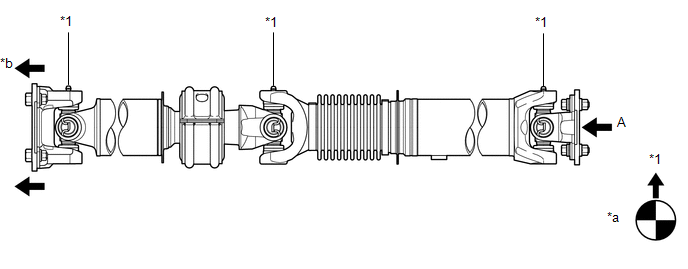

1. INSPECT PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY (with Grease Fitting)

Text in Illustration

Text in Illustration

|

*1 |

Grease Fitting |

- |

- |

|

*a |

View A |

*b |

Front Side |

HINT:

When replacing the spider bearing, make sure that the grease fitting assembly hole is facing in the direction shown in the illustration.

2. INSTALL PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY

|

(a) Align the matchmarks on the propeller shaft flange yoke and transfer flange. Text in Illustration

|

|

(b) Install the propeller shaft with the 4 nuts and 4 washers.

Torque:

88 N·m {899 kgf·cm, 65 ft·lbf}

|

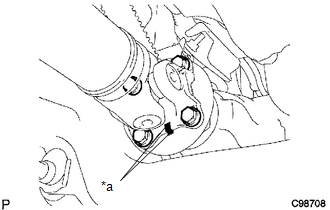

(c) Align the matchmarks on the propeller shaft flange yoke and differential flange. Text in Illustration

|

|

(d) for Differential Type BD20:

(1) Install the propeller shaft with the 4 bolts, 4 washers and 4 nuts.

Torque:

88 N·m {899 kgf·cm, 65 ft·lbf}

(e) for Differential Type BD22:

(1) Install the propeller shaft with the 4 washers and 4 nuts.

Torque:

88 N·m {899 kgf·cm, 65 ft·lbf}

|

(f) Provisionally install the center support bearing with 2 mounting bolts. Text in Illustration

HINT: Make sure the bearing is installed with the drain hole facing downwards. |

|

(g) Tighten the 2 bolts.

Torque:

36 N·m {369 kgf·cm, 27 ft·lbf}

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY

(a) Using a dial indicator, check the propeller shaft runout.

Maximum runout:

0.6 mm (0.0236 in.)

If the shaft run ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSPECT CENTER NO. 2 SUPPORT BEARING ASSEMBLY

(a) Turn the center bearing by hand, check that it turns smoothly without catching

and that there are no cracks or damage.

...

Other materials:

System Diagram

SYSTEM DIAGRAM

Communication Table

Transmitting ECU (Transmitter)

Receiving ECU (Receiver)

Signal

Line

Certification ECU

(Smart Key ECU Assembly)

Main Body ECU

(Multiplex Network Body ECU)

...

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

Air Conditioning System

DTC Code

Detection Item

Memory

See page

B1411/11

Room Temperature Sensor Circuit

Memorized

(4 seconds or more)

B1412/12

...

AUTO LSD Indicator Light Remains ON

DESCRIPTION

During normal mode, pressing the VSC OFF switch for a short amount of time changes

vehicle to AUTO LSD mode.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

When replacing the skid control ECU (master cylinder solenoid), perform

calibration (See page

).

Inspe ...