Toyota Tacoma (2015-2018) Service Manual: Inspection

INSPECTION

PROCEDURE

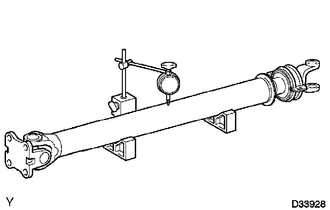

1. INSPECT PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY

(a) Using a dial indicator, check the propeller shaft runout.

Maximum runout:

0.6 mm (0.0236 in.)

If the shaft runout is greater than the maximum, replace the shaft.

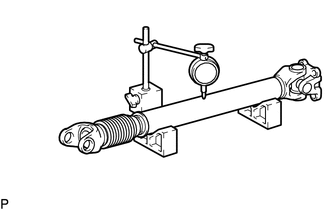

2. INSPECT PROPELLER SHAFT

(a) Using a dial indicator, check the propeller shaft runout.

Maximum runout:

0.6 mm (0.0236 in.)

If the shaft runout is greater than the maximum, replace the shaft.

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE REAR PROPELLER SHAFT BOOT CLAMP

(a) Place matchmarks on the propeller shaft and sleeve yoke.

Text in Illustration

*1

...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSPECT PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY (with Grease Fitting)

Text in Illustration

*1

Grease Fitting

-

-

...

Other materials:

Installation

INSTALLATION

PROCEDURE

1. INSTALL FLYWHEEL HOUSING SIDE COVER

(a) Install the flywheel housing side cover to the cylinder block sub-assembly.

2. INSTALL STARTER ASSEMBLY

(a) Install the starter assembly with the 2 bolts.

Torque:

37 N·m {377 kgf·cm, 27 ft·lbf}

(b) Connect the engine wire ...

Data Signal Circuit between Radio Receiver and Stereo Jack Adapter

DESCRIPTION

The No. 1 stereo jack adapter assembly sends the sound data signal or image data

signal from a USB device to the radio and display receiver assembly via this circuit.

WIRING DIAGRAM

PROCEDURE

1.

CHECK HARNESS AND CONNECTOR (RADIO AND DISPLAY RECEIVER ASSEMB ...

Sensor (Motor) Failure (B2341,B2344)

DESCRIPTION

When the sliding roof ECU (sliding roof drive gear sub-assembly) detects a motor

malfunction and the sliding roof operation is stopped, DTC B2341 is stored.

When the sliding roof ECU (sliding roof drive gear sub-assembly) detects a gear

position malfunction and the sliding roof ope ...