Toyota Tacoma (2015-2018) Service Manual: Installation

INSTALLATION

PROCEDURE

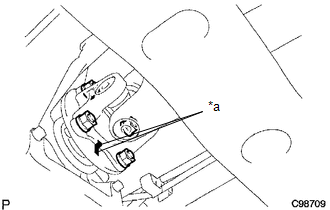

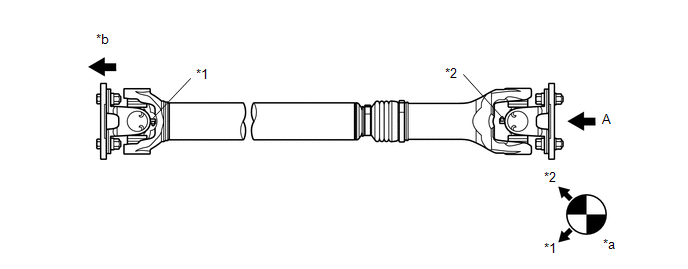

1. INSPECT FRONT PROPELLER SHAFT ASSEMBLY (with Grease Fitting)

HINT:

When replacing the spider bearing, make sure that the grease fitting assembly hole is facing in the direction shown in the illustration.

Text in Illustration

Text in Illustration

|

*1 |

No. 1 Grease Fitting |

*2 |

No. 2 Grease Fitting |

|

*a |

View A |

*b |

Front Side |

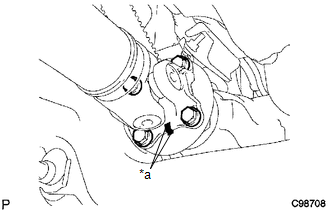

2. INSTALL FRONT PROPELLER SHAFT ASSEMBLY

(a) Align the matchmarks on the propeller shaft flange and differential flange.

Text in Illustration|

*a |

Matchmark |

(b) Install the propeller shaft with the 4 bolts, 4 nuts and 4 washers.

Torque:

88 N·m {899 kgf·cm, 65 ft·lbf}

|

(c) Align the matchmarks on the propeller shaft flange and transfer flange. Text in Illustration

|

|

(d) Install the propeller shaft with the 4 nuts and 4 washers.

Torque:

88 N·m {899 kgf·cm, 65 ft·lbf}

3. INSTALL PROPELLER SHAFT HEAT INSULATOR BRACKET SUB-ASSEMBLY

.png)

(a) Install the propeller shaft heat insulator bracket with the 2 bolts.

Torque:

16 N·m {160 kgf·cm, 12 ft·lbf}

4. INSTALL FRONT NO. 2 EXHAUST PIPE ASSEMBLY (for 2GR-FKS)

.gif)

.gif)

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL FRONT PROPELLER SHAFT UNIVERSAL JOINT SPIDER BEARING

(a) Apply MP grease to a new spider and spider bearing.

(b) Fit the spider into the flange yoke.

...

Other materials:

Clearance Sonar Main Switch Circuit

DESCRIPTION

The back sonar or clearance sonar switch assembly is installed at the base of

the driver side of the instrument panel.

When the back sonar or clearance sonar switch assembly is turned on, an on signal

is sent to the clearance warning ECU assembly. The intuitive parking assist syste ...

Precaution

PRECAUTION

PRECAUTION WHEN REPLACING COMBINATION METER ASSEMBLY

(a) When replacing the combination meter assembly, always replace it with a new

one. If a combination meter assembly which was installed to another vehicle is used,

the information stored in it will not match the information from ...

Operation Check

OPERATION CHECK

1. INSPECT INTERIOR LIGHT CONTROL OPERATION

NOTICE:

Perform this inspection with the customize parameters at the default settings.

The interior light control illuminates the lights below.

Engine Switch Illumination*1

Transponder Key Coil (Ignition Key Cylinder Light)* ...