Toyota Tacoma (2005–2015) Owners Manual: Headlight switch

The headlights can be operated manually.

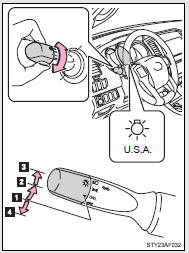

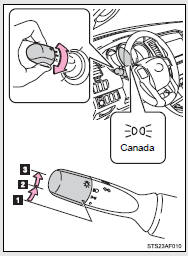

Turning the end of the lever turns on the lights as follows:

Type A

Type A

The daytime running lights turn

on.

The daytime running lights turn

on.

The side marker, parking, tail,

license plate, daytime running lights and instrument panel lights turn on.

The side marker, parking, tail,

license plate, daytime running lights and instrument panel lights turn on.

The headlights and all lights listed

above (except daytime running lights) turn on.

The headlights and all lights listed

above (except daytime running lights) turn on.

The daytime running lights turn

off.

The daytime running lights turn

off.

Type B

Type B

The daytime running lights turn

on.

The daytime running lights turn

on.

The side marker, parking, tail,

license plate, daytime running lights and instrument panel lights turn on.

The side marker, parking, tail,

license plate, daytime running lights and instrument panel lights turn on.

The headlights and all lights listed

above (except daytime running lights) turn on.

The headlights and all lights listed

above (except daytime running lights) turn on.

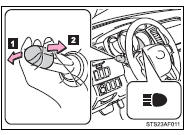

Turning on the high beam headlights

With the headlights on, push the

lever forward to turn on the high beams.

With the headlights on, push the

lever forward to turn on the high beams.

Pull the lever back to the center position to turn the high beams off.

Pull the lever toward you to turn

on the high beams.

Pull the lever toward you to turn

on the high beams.

Release the lever to turn them off.

You can flash the high beams with the headlights on or off.

■Daytime running light system

●To make your vehicle more visible to other drivers, the front turn signal lights turn on automatically whenever the engine is started and the parking brake is released. Daytime running lights are not designed for use at night.

Type A: Daytime running lights can be turned off by operating the switch.

●Compared to turning on the headlights, the daytime running light system offers greater durability and consumes less electricity, so it can help improve fuel economy.

■Automatic light off system

Opening the driver’s door with the engine switch in the ACC or LOCK position will turn the headlights and tail lights off.

To turn the lights on again, turn the engine switch to the ON position, or turn

the headlight switch off once and then back to the

or

or

position.

position.

NOTICE

■To prevent battery discharge

Do not leave the lights on longer than necessary when the engine is not running.

Fog light switch

Fog light switch

The fog lights improve visibility in difficult driving conditions, such as

in rain or fog.

■The fog lights can be turned on only when

The headlights are on low beam. ...

Other materials:

Pressure Sensor or Switch (C1254)

DESCRIPTION

The accumulator pressure sensor is connected to the skid control ECU in the master

cylinder solenoid.

DTC No.

DTC Detecting Condition

Trouble Areas

C1254

Accumulator pressure sensor fault

(Fluid pressure does not chang ...

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repairs" after replacing the fuel pump assembly (See

page ).

PROCEDURE

1. SET FUEL PUMP ASSEMBLY

HINT:

Perform "Inspection After Repairs" after replacing the fuel pump assembly (See

page ).

...

Rear Body Side Panel Protector

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The following procedure is for the LH side.

PROCEDURE

1. INSTALL REAR BODY SIDE PANEL PROTECTOR

(a) for Sho ...