Toyota Tacoma (2015-2018) Service Manual: Disassembly

DISASSEMBLY

PROCEDURE

1. INSPECT FRONT PROPELLER SHAFT UNIVERSAL JOINT SPIDER BEARING

(a) Check the spider bearings for wear and damage.

(b) Check each spider bearing's axial play by turning the yoke while holding the shaft tightly.

Maximum bearing axial play:

0 to 0.05 mm (0 to 0.002 in.)

2. REMOVE FRONT PROPELLER SHAFT UNIVERSAL JOINT SPIDER BEARING

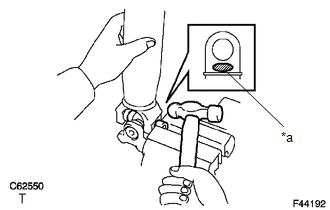

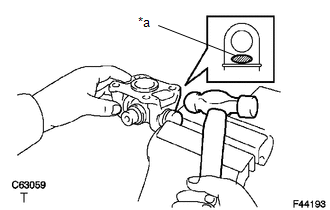

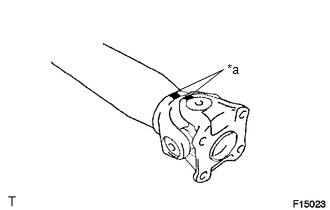

(a) Place matchmarks on the propeller shaft and flange yoke.

Text in Illustration|

*a |

Matchmark |

|

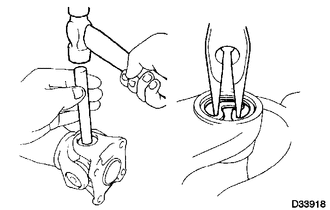

(b) Using a brass bar and a hammer, slightly tap in the spider bearing outer races. |

|

(c) Using needle-nose pliers, remove the 4 snap rings from the grooves.

|

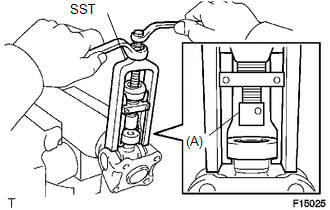

(d) Using SST, push the spider bearing out of the propeller shaft. SST: 09332-25010 HINT: Sufficiently raise the part indicated by (A) so that it does not come into contact with the spider bearing. |

|

|

(e) Clamp the spider bearing outer race in a vise and tap off the propeller shaft with a hammer. HINT: Remove the bearing on the opposite side in the same procedure. Text in Illustration

NOTICE: Do not tap the shaft. |

|

|

(f) Install the 2 removed spider bearing outer races onto the spider, and clamp them in a vise. |

|

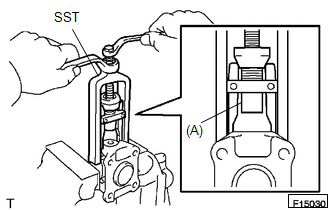

(g) Using SST, push the bearing out of the yoke.

SST: 09332-25010

HINT:

Sufficiently raise the part indicated by (A) so that it does not come into contact with the bearing.

|

(h) Clamp the outer bearing race in a vise and tap off the flange yoke with a hammer. Text in Illustration

|

|

(i) Remove the spider.

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT NO. 2 EXHAUST PIPE ASSEMBLY (for 2GR-FKS)

2. REMOVE PROPELLER SHAFT HEAT INSULATOR BRACKET SUB-ASSEMBLY

(a) Remove the 2 bolts and propeller shaft heat insu ...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT PROPELLER SHAFT ASSEMBLY

(a) Using a dial indicator, check the propeller shaft runout.

Maximum runout:

0.6 mm (0.024 in.)

If the shaft runout is greater ...

Other materials:

High Power Supply Voltage Malfunction (C1417)

DESCRIPTION

If a malfunction is detected in the power supply circuit, the skid control ECU

(housed in the master cylinder solenoid) stores this DTC and the fail-safe function

prohibits ABS/VSC/TRAC operation.

This DTC is stored when the IG1 terminal voltage deviates from the DTC detection

co ...

Rear Differential Lock Position SW Stuck OFF (P17BB)

DESCRIPTION

This DTC is output when an OFF malfunction of the differential lock indicator

switch is detected.

DTC No.

Detection Item

DTC Detection Condition

Trouble Area

P17BB

Rear Differential Lock Position SW Stuck OFF

...

Open in ABS Solenoid Relay Circuit (C146E,C146F)

DESCRIPTION

The ABS solenoid relay is built into the master cylinder solenoid.

This relay supplies power to each ABS solenoid. After the ignition switch is

turned ON, if the initial check is OK, the relay turns on.

DTC No.

DTC Detecting Conditions

Trouble Areas

...