Toyota Tacoma (2015-2018) Service Manual: Automatic Disconnecting Differential Motor Limit Switch Circuit (P17A4)

DESCRIPTION

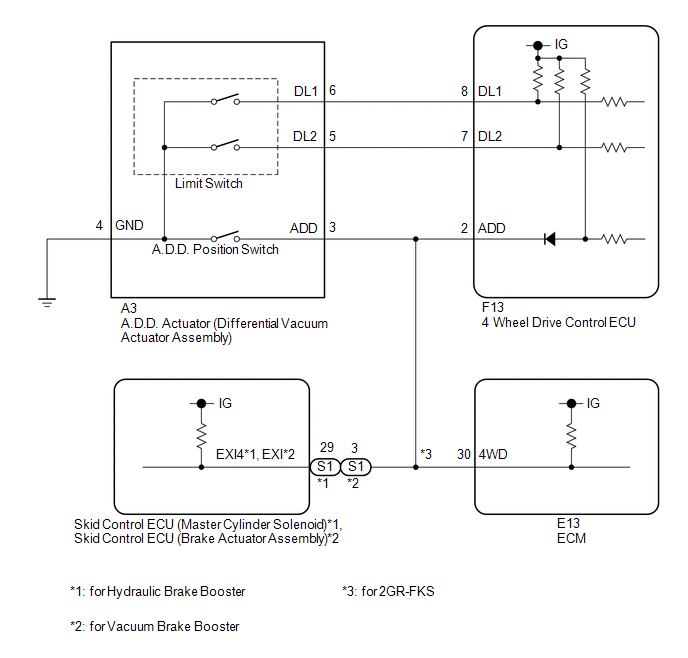

When the A.D.D. actuator switches between 2WD and 4WD, the DL1 and DL2 terminals of the limit switch and ADD terminal of the A.D.D. position switch change to one of the following ON/OFF combinations listed in the table below.

|

Terminal |

In 2WD |

Switching between 2WD and 4WD |

In 4WD |

|

|---|---|---|---|---|

|

DL1 |

ON (GND) |

ON (GND) |

OFF (OPEN) |

|

|

DL2 |

OFF (OPEN) |

ON (GND) |

ON (GND) |

|

|

ADD |

OFF (OPEN) |

OFF (OPEN) |

ON (GND) |

ON (GND) |

A malfunction is detected depending on the combination of the 3 circuits that make up the limit switch and A.D.D. position switch.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

|---|---|---|---|

|

P17A4 |

Automatic Disconnecting Differential Motor Limit Switch Circuit |

|

|

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (4 WHEEL DRIVE CONTROL ECU - DIFFERENTIAL VACUUM ACTUATOR ASSEMBLY) |

(a) Disconnect the F13 4 wheel drive control ECU connector.

(b) Disconnect the A3 A.D.D. actuator (differential vacuum actuator assembly) connector.

(c) for Hydraulic Brake Booster:

Disconnect the S1 skid control ECU (Master Cylinder Solenoid) connector.

for Vacuum Brake Booster:

Disconnect the S1 skid control ECU (brake actuator assembly) connector.

(d) for 2GR-FKS:

Disconnect the E13 ECM connector.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F13-8 (DL1) - A3-6 (DL1) |

Always |

Below 1 Ω |

|

F13-7 (DL2) - A3-5 (DL2) |

Always |

Below 1 Ω |

|

F13-2 (ADD) - A3-3 (ADD) |

Always |

Below 1 Ω |

|

A3-4 (GND) - Body ground |

Always |

Below 1 Ω |

|

F13-8 (DL1) or A3-6 (DL1) - Body ground |

Always |

10 kΩ or higher |

|

F13-7 (DL2) or A3-5 (DL2) - Body ground |

Always |

10 kΩ or higher |

|

F13-2 (ADD) or A3-3 (ADD) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

2. |

INSPECT DIFFERENTIAL VACUUM ACTUATOR ASSEMBLY (LIMIT SWITCH AND A.D.D. POSITION SWITCH) |

|

(a) Disconnect the A.D.D. actuator (differential vacuum actuator assembly) connector. |

|

(b) for Hydraulic Brake Booster:

Disconnect the S1 skid control ECU (Master Cylinder Solenoid) connector.

for Vacuum Brake Booster:

Disconnect the S1 skid control ECU (brake actuator assembly) connector.

(c) for 2GR-FKS:

Disconnect the E13 ECM connector.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

A3-6 (DL1) - Body ground |

Ignition switch ON |

10 to 14 V |

|

A3-5 (DL2) - Body ground |

Ignition switch ON |

10 to 14 V |

|

A3-3 (ADD) - Body ground |

Ignition switch ON |

10 to 14 V |

|

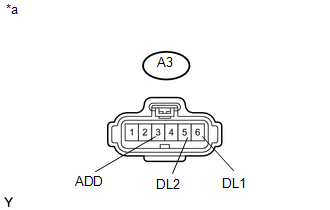

*a |

Front view of wire harness connector (to A.D.D. Actuator (Differential Vacuum Actuator Assembly)) |

| OK | .gif) |

REPLACE DIFFERENTIAL VACUUM ACTUATOR ASSEMBLY |

| NG | .gif) |

REPLACE 4 WHEEL DRIVE CONTROL ECU |

Automatic Disconnecting Differential Motor Control Circuit Open (P17A0)

Automatic Disconnecting Differential Motor Control Circuit Open (P17A0)

DESCRIPTION

This DTC is output when an open circuit in the A.D.D. shift motor drive circuit

is detected.

DTC No.

Detection Item

DTC Detection Condition

...

Transfer Shift Motor Control Circuit Circuit Open (P17A8)

Transfer Shift Motor Control Circuit Circuit Open (P17A8)

DESCRIPTION

This DTC is output when an open circuit in the transfer shift motor drive circuit

is detected.

DTC No.

Detection Item

DTC Detection Condition

...

Other materials:

Terminals Of Ecu

TERMINALS OF ECU

1. CHECK 4 WHEEL DRIVE CONTROL ECU

Text in Illustration

*a

Component with harness connected

(4 Wheel Drive Control ECU)

-

-

(a) Measure the resistance and voltage according to the value(s) in the table

below.

...

System Description

SYSTEM DESCRIPTION

1. DESCRIPTION

A part-time 2-speed VF2CM transfer uses a touch select 2-4 and high-low

system, enabling the driver to switch between 2WD, H4 and L4 modes by turning

the transfer position switch.

Through these switch signals, the 4 wheel drive control ECU actua ...

Dtc Check / Clear

DTC CHECK / CLEAR

1. CHECK DTC

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Main Body / Trouble Codes.

(e) Check for DTCs.

2. CLEAR DTC

(a) Connect the Techstream to the DLC3.

(b) Turn t ...

.gif)