Toyota Tacoma (2015-2018) Service Manual: Air Conditioning Compressor Magnetic Clutch Circuit

DESCRIPTION

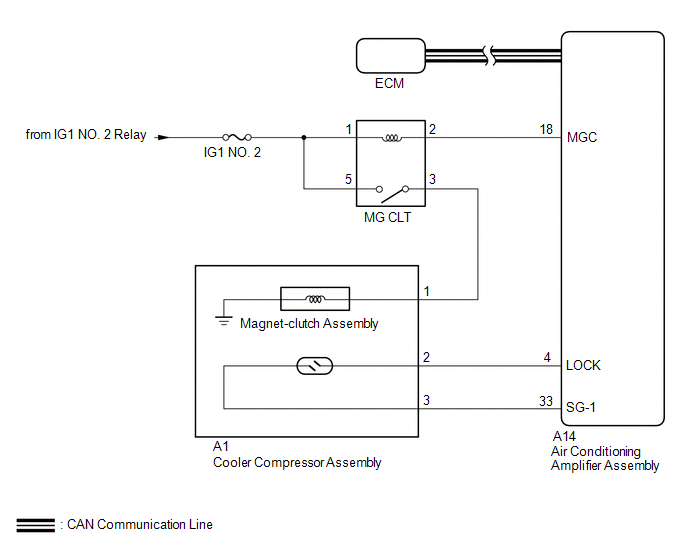

When the air conditioning amplifier assembly is turned on, a magnetic clutch on signal is sent from the MGC terminal of the air conditioning amplifier assembly. Then, the MG CLT relay turns on to operate the magnetic clutch assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- ECM malfunctions can affect the storage of this DTC. Therefore, check

all SFI system DTCs and confirm that the system is normal before performing

the following inspection.

- for 2TR-FE (See page

.gif) )

) - for 2GR-FKS (See page

.gif) )

)

- for 2TR-FE (See page

- Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

|

1. |

CHECK FOR DTC (CAN COMMUNICATION SYSTEM) |

(a) Use the Techstream to check if the CAN communication system is functioning normally.

Result|

Result |

Proceed to |

|---|---|

|

CAN DTC is not output |

A |

|

CAN DTC is output |

B |

| B | .gif) |

GO TO CAN COMMUNICATION SYSTEM |

|

|

2. |

INSPECT MG CLT RELAY |

(a) Remove the MG CLT relay.

(b) Inspect the MG CLT relay (See page .gif) ).

).

| NG | .gif) |

REPLACE MG CLT RELAY |

|

|

3. |

CHECK HARNESS AND CONNECTOR (MG CLT RELAY - POWER SOURCE CIRCUIT) |

(a) Remove the MG CLT relay.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

MG CLT-1 - Body ground |

Ignition switch ON |

11 to 14 V |

|

MG CLT-5 - Body ground |

Ignition switch ON |

11 to 14 V |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

CHECK HARNESS AND CONNECTOR (MG CLT RELAY - AIR CONDITIONING AMPLIFIER ASSEMBLY AND MAGNET-CLUTCH ASSEMBLY) |

(a) Remove the MG CLT relay.

(b) Disconnect the A14 air conditioning amplifier assembly connector.

(c) Disconnect the A1 magnet-clutch assembly connector.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

MG CLT-2 - A14-18 (MGC) |

Always |

Below 1 Ω |

|

MG CLT-3 - A1-1 (MG+) |

Always |

Below 1 Ω |

|

MG CLT-2 or A14-18 (MGC) - Body ground |

Always |

10 kΩ or higher |

|

MG CLT-3 or A1-1 (MG+) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

INSPECT MAGNET-CLUTCH ASSEMBLY |

(a) Remove the magnet-clutch assembly (See page

.gif)

.gif) ).

).

(b) Inspect the magnet-clutch assembly (See page

.gif) ).

).

| NG | .gif) |

REPLACE MAGNET-CLUTCH ASSEMBLY |

|

|

6. |

INSPECT AIR CONDITIONING AMPLIFIER ASSEMBLY |

(a) Reconnect the A14 air conditioning amplifier assembly connector.

(b) Reconnect the A1 magnet-clutch assembly connector.

(c) Reinstall the MG CLT relay.

|

(d) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

Lost Communication with ECM (U0100,U0142,U0155)

Lost Communication with ECM (U0100,U0142,U0155)

DESCRIPTION

DTC No.

DTC Detecting Condition

Trouble Area

U0100

No communication with ECM

CAN communication system

...

Evaporator Temperature Sensor Circuit (B1413)

Evaporator Temperature Sensor Circuit (B1413)

DESCRIPTION

The cooler thermistor sensor (evaporator temperature sensor) is installed on

the evaporator in the air conditioner unit to detect the temperature of the cooled

air that has passed thr ...

Other materials:

ABS Warning Light Remains ON

DESCRIPTION

If any of the following is detected, the ABS warning light remains on.

The skid control ECU (master cylinder solenoid) connectors are disconnected

from the skid control ECU (master cylinder solenoid).

There is a malfunction in the skid control ECU (master cylinder soleno ...

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Ptc Heater Assembly

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE LOWER NO. 2 INSTRUMENT PANEL AIRBAG ASSEMBLY

(See page )

2. REMOVE INSTRUMENT LOWER PANEL ASSEMBLY

3. REMOVE AIR DUCT ASSEMBLY

4. REMOVE QUICK HEATER ASSEMBLY

(a) Disconnect the connector.

...

.gif)