Toyota Tacoma (2015-2018) Service Manual: Acceleration Sensor Stuck Malfunction (C1232,C1243,C1245,C1279)

DESCRIPTION

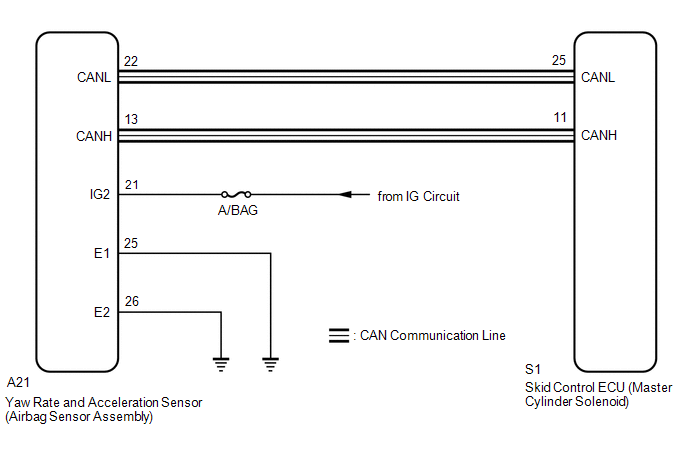

The skid control ECU (master cylinder solenoid) receives signals from the yaw rate and acceleration (airbag sensor assembly) via the CAN communication system.

The airbag sensor assembly has a built-in yaw rate and acceleration sensor and detects the vehicle's condition using 2 circuits (GL1, GL2).

If there is trouble in the bus lines between the yaw rate and acceleration sensor (airbag sensor assembly) and the CAN communication system, DTCs U0123 (yaw rate sensor communication trouble) and U0124 (acceleration sensor communication trouble) are stored.

These DTCs are also output when calibration has not been completed.

|

DTC Code |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

C1232 |

At vehicle speed of 10 km/h (6 mph) or more, signal from either GL1 or GL2 does not change for 30 seconds or more. |

|

|

C1243 |

Following condition repeats 16 times.

|

|

|

C1245 |

Following condition continues for at least 60 seconds.

|

|

|

C1279 |

Detected only during test mode |

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- When replacing the yaw rate and acceleration sensor (airbag sensor assembly),

perform zero point calibration (See page

.gif)

.gif) ).

). - Inspect the fuses for circuits related to this system before performing the following inspection procedure.

HINT:

When U0073, U0100, U0123, U0124 or U0126 are output together with C1232 or C1234, inspect and repair the trouble areas indicated by U0073, U0100, U0123, U0124 or U0126 first.

PROCEDURE

|

1. |

CHECK DTC |

(a) Clear the DTCs (See page .gif)

.gif) ).

).

(b) Turn the ignition switch off.

(c) Check if DTCs U0073, U0123, C1210 and/or C1336 are output (See page

.gif)

.gif) ).

).

|

Result |

Proceed to |

|---|---|

|

DTC U0073, U0123, C1210 and/or C1336 are not output |

A |

|

DTC U0073 and/or U0123 are output |

B |

|

DTC C1210 and/or C1336 are output |

C |

| B | .gif) |

GO TO CAN COMMUNICATION SYSTEM (HOW TO PROCEED WITH TROUBLESHOOTING) |

| C | .gif) |

REPAIR CIRCUITS INDICATED BY OUTPUT DTCS |

|

|

2. |

CHECK AIRBAG SENSOR ASSEMBLY INSTALLATION |

(a) Check that the yaw rate and acceleration sensor (airbag sensor assembly)

is installed properly (See page .gif)

.gif) ).

).

OK:

The sensor is tightened to the specified torque.

The sensor is not tilted.

| NG | .gif) |

INSTALL AIRBAG SENSOR ASSEMBLY CORRECTLY |

|

|

3. |

CHECK HARNESS AND CONNECTOR (IG2, E1, E2 TERMINAL) |

|

(a) Disconnect the yaw rate and acceleration sensor (airbag sensor assembly) connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

A21-21 (IG2) - Body ground |

Ignition switch ON |

11 to 14 V |

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A21-25 (E1) - Body ground |

Always |

Below 1 Ω |

|

A21-26 (E2) - Body ground |

Always |

Below 1 Ω |

|

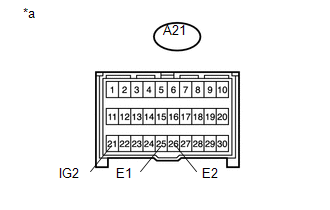

*a |

Front view of wire harness connector (to Yaw Rate and Acceleration Sensor (Airbag Sensor Assembly)) |

|

Result |

Proceed to |

|---|---|

|

OK (When troubleshooting in accordance with Diagnostic Trouble Code Chart) |

A |

|

OK (When troubleshooting in accordance with Problem Symptoms Table) |

B |

|

NG |

C |

| A | .gif) |

REPLACE AIRBAG SENSOR ASSEMBLY |

| B | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| C | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

SM Solenoid Circuit (C1225-C1228,C1468,C1469,C146A,C146B)

SM Solenoid Circuit (C1225-C1228,C1468,C1469,C146A,C146B)

DESCRIPTION

The solenoid goes on when signals are received from the skid control ECU (master

cylinder solenoid) and controls the pressure action on the wheel cylinders thus

controlling the brakin ...

Low Power Supply Voltage Malfunction (C1241)

Low Power Supply Voltage Malfunction (C1241)

DESCRIPTION

If there is a problem with the skid control ECU (master cylinder solenoid) power

supply circuit, the skid control ECU outputs the DTC and prohibits operation under

the fail-safe funct ...

Other materials:

Data Signal Circuit between Navigation Receiver Assembly and Extension Module

DESCRIPTION

The stereo component tuner assembly sends the sound data signal or image data

signal from a device to the navigation receiver assembly via this circuit.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

After replacing the stereo component tuner assembly of vehicles subscribed to

...

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

The 4 wheel drive control ECU records DTCs when the ECU detects a malfunction

in the ECU itself or in system circuits.

The DTCs can be read through the DLC3 of the vehicle. When the system seems to

be malfunctioning, use the Techstream to check for malfunctions ...

Freeze Frame Data

FREEZE FRAME DATA

1. FREEZE FRAME DATA

(a) Whenever a meter DTC is detected, the combination meter assembly stores the

current vehicle state as freeze frame data.

2. CHECK FREEZE FRAME DATA

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on ...

.gif)