Toyota Tacoma (2015-2018) Service Manual: Speed Sensor

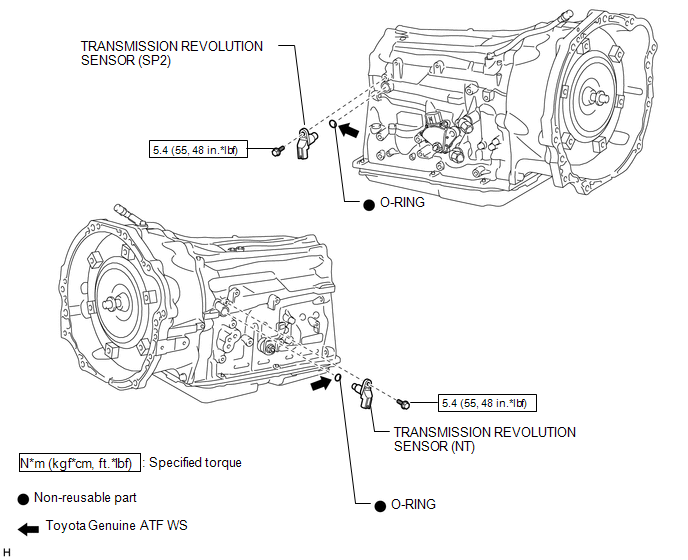

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

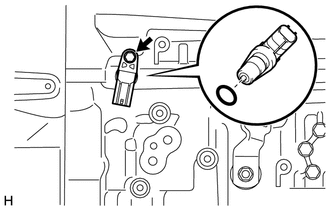

1. REMOVE TRANSMISSION REVOLUTION SENSOR (NT)

|

(a) Disconnect the transmission revolution sensor (NT) connector. |

|

(b) Remove the bolt and transmission revolution sensor (NT).

(c) Remove the O-ring from the transmission revolution sensor (NT).

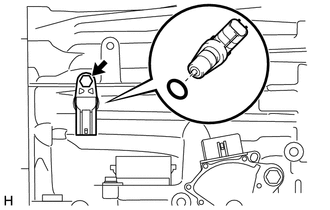

2. REMOVE TRANSMISSION REVOLUTION SENSOR (SP2)

|

(a) Disconnect the transmission revolution sensor (SP2) connector. |

|

(b) Remove the bolt and transmission revolution sensor (SP2).

(c) Remove the O-ring from the transmission revolution sensor (SP2).

Inspection

INSPECTION

PROCEDURE

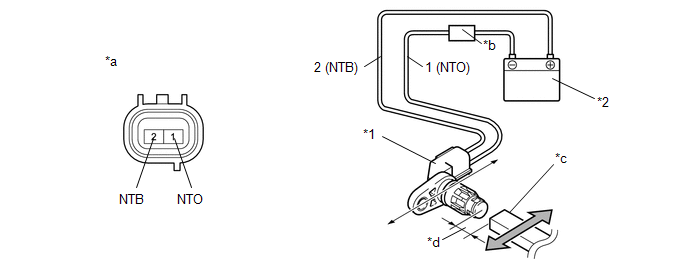

1. INSPECT TRANSMISSION REVOLUTION SENSOR (NT)

(a) Connect the battery to the transmission revolution sensor (NT) as shown in the illustration.

Text in Illustration

Text in Illustration

|

*1 |

Transmission Revolution Sensor (NT) |

*2 |

Battery |

|

*a |

Component without harness connected (Transmission Revolution Sensor (NT)) |

*b |

Ammeter |

|

*c |

Magnet |

*d |

5 mm (0.197 in.) or less |

(b) Wave a magnetic object left and right in front of the transmission revolution sensor (NT) tip (5 mm (0.197 in.) or less) to change the high/low signals while measuring the current.

NOTICE:

Make sure to wave the magnetic object during the inspection. The current will not change without waving the magnetic object as indicated by the arrow in the illustration.

(c) Measure the current according to the value(s) in the table below.

Standard Current:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 (NTO) - 2 (NTB) |

Low signal |

4 to 8 mA |

|

High signal |

12 to 16 mA |

If the result is not as specified, replace the transmission revolution sensor (NT).

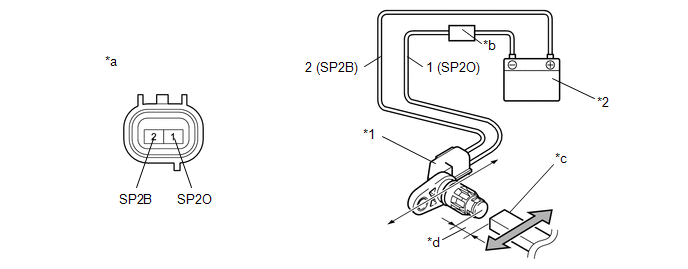

2. INSPECT TRANSMISSION REVOLUTION SENSOR (SP2)

(a) Connect the battery to the transmission revolution sensor (SP2) as shown in the illustration.

Text in Illustration

Text in Illustration

|

*1 |

Transmission Revolution Sensor (SP2) |

*2 |

Battery |

|

*a |

Component without harness connected (Transmission Revolution Sensor (SP2)) |

*b |

Ammeter |

|

*c |

Magnet |

*d |

5 mm (0.197 in.) or less |

(b) Wave a magnetic object left and right in front of the transmission revolution sensor (SP2) tip (5 mm (0.197 in.) or less) to change the high/low signals while measuring the current.

NOTICE:

Make sure to wave the magnetic object during the inspection. The current will not change without waving the magnetic object as indicated by the arrow in the illustration.

(c) Measure the current according to the value(s) in the table below.

Standard Current:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 (SP2O) - 2 (SP2B) |

Low signal |

4 to 8 mA |

|

High signal |

12 to 16 mA |

If the result is not as specified, replace the transmission revolution sensor (SP2).

Installation

INSTALLATION

PROCEDURE

1. INSTALL TRANSMISSION REVOLUTION SENSOR (SP2)

(a) Coat a new O-ring with ATF and install it to the transmission revolution sensor (SP2).

(b) Install the transmission revolution sensor (SP2) with the bolt.

Torque:

5.4 N·m {55 kgf·cm, 48 in·lbf}

(c) Connect the transmission revolution sensor (SP2) connector.

2. INSTALL TRANSMISSION REVOLUTION SENSOR (NT)

(a) Coat a new O-ring with ATF and install it to the transmission revolution sensor (NT).

(b) Install the transmission revolution sensor (NT) with the bolt.

Torque:

5.4 N·m {55 kgf·cm, 48 in·lbf}

(c) Connect the transmission revolution sensor (NT) connector.

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL INDICATOR LIGHT WIRE SUB-ASSEMBLY

(a) Connect the connector to install the indicator light wire sub-assembly

to the shift position indicator.

...

Torque Converter And Drive Plate

Torque Converter And Drive Plate

Inspection

INSPECTION

PROCEDURE

1. INSPECT TORQUE CONVERTER ASSEMBLY

(a) Inspect the one-way clutch.

(1) Press on the spline of the stator with a finger and rotate the spline. Check

that the ...

Other materials:

Wireless Charger Power Source Circuit

DESCRIPTION

This is the power source circuit to operate the mobile wireless charger cradle

assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following

inspection procedure.

PROCEDURE

1.

...

Confirm Vehicle Headunit Functionality

PROCEDURE

1.

CHECK CUSTOMER'S CELLULAR PHONE COMPATIBILITY

(a) Go to TIS "Bluetooth" Compatibility Portal and check if the cellular phone

is compatible.

Result

Result

Proceed to

Cellular phone is compatible

...

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

The wireless door lock control system troubleshooting procedure is based

on the premise that the power door lock control system is operating normally.

Check the power door lock control system first before troubleshooting the

wireless door lock cont ...